LDF Series | Mobile High Power Diode Laser

Diode lasers for industrial applications in the multi-kilowatt range set the standard in terms of performance, mobility, efficiency and ease of maintenance

Diode lasers for industrial applications in the multi-kilowatt range set the standard in terms of performance, mobility, efficiency and ease of maintenance

With the LDF series Laserline is setting the benchmarks for high power diode lasers. Even devices with over 30 kW laser power are set on sturdy castors allowing a single employee to move the laser to different locations for start-up in production – a unique benefit. All you need is electricity, water and an optical fiber – and the laser is ready for use at its new site.

Thanks to permanent development of our proven active diode cooling technology the LDF series family is optimized to multi-kilowatt power levels even at high beam qualities: 8 kW out of a 600 µm fiber at NA 0.1 in a compact configuration at less than one square meter footprint.

Be it power, cooling or system interfaces: The LDF series can be individually configured and adapted to changing requirements. The lasers are available with internal or external cooling system as a water/water or water/air variant.

With these Laserline chillers, perfectly aligned to the product line and fully integrated in the control cycle, high power lasers can now be operated permanently in production with a low footprint requirement. Through the internal networking of all components malfunctions can be diagnosed in real-time and resolved immediately.

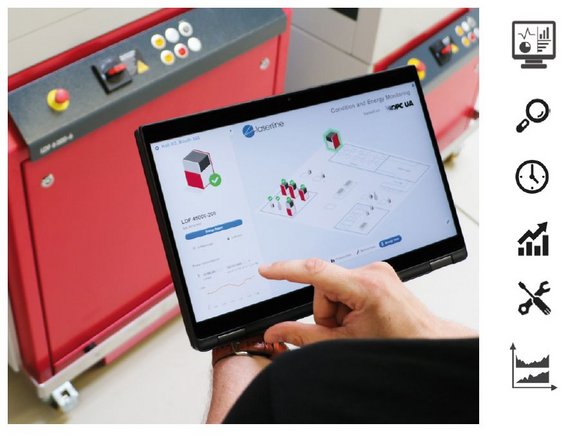

LDF diode lasers are highly economical: with an efficiency of over 50 percent, they have the highest technical efficiency of all laser types. And the functionality leaves nothing to be desired: Thanks to the mobile hot-pluggable operating unit, the LDF lasers can be monitored and controlled very flexibly, even from a distance.

The three-stage troubleshooting management system displays information, warning and error messages, identifies causes and, if necessary, guides you directly to efficient troubleshooting.

Connection areas and interfaces are easily accessible thanks to a pull-out cover. System components can be easily replaced - so production does not come to a standstill.

An OPC UA interface creates the prerequisites for platform-independent, vertical and horizontal data communication. It enables the integration of lasers, fibers and processing optics in modern system architectures and forms the basis for new digital laser solutions.

Optical Specifications

| Max. output power | 8,000 W | 11,000 W | 16,000 W | 30,000 W | 45,000 W | |

|---|---|---|---|---|---|---|

| Beam quality | 30 mm.mrad | 40 mm.mrad | 60 mm.mrad | 100 mm.mrad | 200 mm.mrad | |

| Other laser powers and process adapted beam qualities available | ||||||

| Optical fiber | 600 µm[NA 0.1] | 400 µm[NA 0.2] | 600 µm[NA 0.2] | 1,000 µm[NA 0.2] | 2,000 µm[NA 0.2] | |

| Fiber length | 10m, 20m, 30m, 50m, other lengths on request | |||||

| Power stability | < ± 2% over 2 hours | |||||

| Wavelength range | 900 nm to 1,080 nm | |||||

Mechanical Specifications

| VG64 | Weight approx. 750 kg, dimensions: 1,012 x 680 x 1,599 mm³ (length x width x height) |

|---|---|

| VG64L | Weight approx. 800 kg, dimensions: 1,012 x 680 x 1,877 mm³ (length x width x height) |

| VG66 | Weight approx. 800 kg, dimensions: 1,065 x 850 x 1,845 mm³ (length x width x height) |

| VG68 | Weight approx. 900 kg, dimensions: 1,409 x 1,227 x 1,865 mm³ (length x width x height) |

Thanks to their high modularity and flexibility, our LDF mobile high power diode lasers are suitable for a wide range of applications. A selection of the most common applications with diode lasers can be found here.

Any questions on our lasers?

Please send us your request!