Laser Welding Aluminum

The advantages of diode lasers in aluminum welding are a quiet melt pool with clean, virtually spatter-free welding and spot parameters that can be precisely adjusted to the application.

Find out moreThe advantages of diode lasers in aluminum welding are a quiet melt pool with clean, virtually spatter-free welding and spot parameters that can be precisely adjusted to the application.

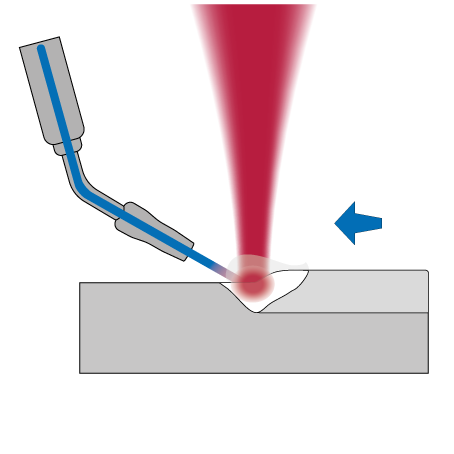

Find out moreAs with all welding processes, the joining zones of the two components to be joined are locally melted by a targeted heat input, in this case by a diode laser. The melts of the two components flow into each other, cool down and form a solid joint after solidification.

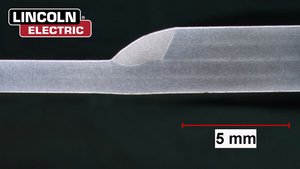

Since the individual alloy components of the aluminum solidify at different temperatures, there is a risk of hot cracks due to the shrinkage stresses occurring in the microstructure during cooling. These would significantly reduce the strength of the welded joint. To avoid hot cracks, a filler wire of aluminum silicon (AlSi) is therefore added to optimize aluminum weldability. The weld produced in this way not only has excellent strength but is also visually appealing and requires no post-processing.

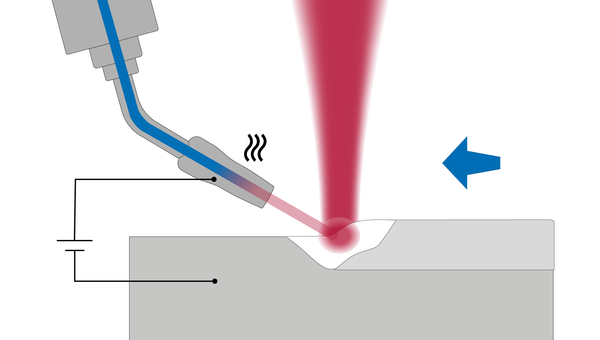

In hot wire welding, electrical current is passed through and pre-heats the filler wire using Joule resistance heating before the laser completes melting to a liquid state. Liquid metals absorb laser energy at much higher rate. The less laser energy has to be introduced to liquefy the filler wire, the more efficient the laser becomes in the process. Put simply, in the hot wire process, the electrical power substitutes laser power that is no longer applied to melt the filler wire. Overall, there are positive effects on the energy footprint and process stability. Significant process advantages are associated with the laser hot-wire process: the heat input and the heat-affected zone are smaller compared to other welding processes, reducing distortion. In addition, higher process speeds can be achieved at high weld grades. The weld seam quality is excellent.

Explore why a laser hot wire process can outperform conventional welding methods in aluminum joining and how new applications in e-mobility, such as aluminum battery tray welding, can benefit from it. Read more

In close cooperation with our customers, Laserline application specialists develop the right setup for aluminum welding processes and optimize the process parameters ready for series production. Do you have a task for us?

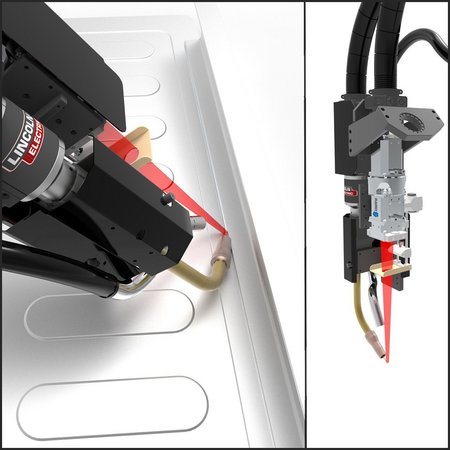

by Lincoln Electric©

Modern electric vehicles are powered by a battery pack, which is usually housed in an aluminum box. These boxes vary in size depending on the vehicle, but all the components of the battery boxes require some kind of joining in the production process. A number of different solutions are in use and being tested for this purpose. All methods must ensure a safe product with a complete seal to prevent environmental elements from entering the pack.

Welding is a preferred method, but besides longer production times, conventional methods such as MIG can also lead to distortion and thus to tolerance problems in further assembly steps in vehicle production. Due to the materials being used, neither autogenous welding nor friction stir are a fit as there will be concerns of post weld cracking in both processes.

A new system solution for battery tray welding is based on hot wire laser welding and avoids these disadvantages. This process is known as Precision Power Laser by Lincoln Electric.

It delivers TIG welding quality at 2-3 times MIG welding speed; A high-quality deposit at high travel speeds with almost infinite control over all aspects of the weld. As a completely non-synergic process, no longer are the limitations of an arc defining factors in weld speed, size, and quality. Travel speeds in excess of 3m/min are possible, depending on material thickness and laser power being used.

| PLaser | 6 kW |

| PWire | 0.8 kW |

| Vs | 1.3 m/min |

| VWire | 4.6 m/min |

| Material Thickness | 3.0 mm |

| Wire Specification | 1.2 mm AlMg5 |

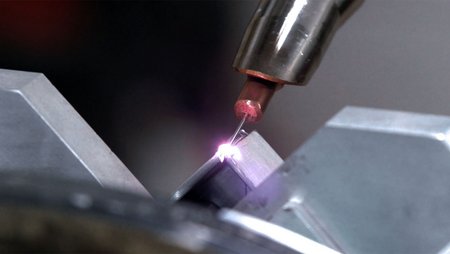

Being flexible is what makes the combination of hot-wire with laser so applicable for a variety of materials and applications throughout many industries. This means it can be a better choice over traditional MIG and TIG in processes such as cladding, brazing, welding and additive manufacturing; especially in situations where distortion must be mitigated. As it happens, adding heat through the filler metal has proven to be a very efficient way of increasing deposition rates and travel speeds while reducing overall heat input.

As a result, a hot wire/laser process can typically achieve higher process speeds with lower heat input and with less metallurgical change to the base material. All of these factors significantly reduce distortion. In situations where speed and quality are critical, the hot-wire/laser process can deliver its full benefits. Depending on material thickness and laser power, welding speeds of over 3 m/min are possible.

| PLaser | 6 kW |

| PWire | 0.8 kW |

| Vs | 3.0 m/min |

| VWire | 4.6 m/min |

| Thickness | 1.5 mm |

Welding aluminum battery boxes with an LDF 6000-6 converter laser offers a number of advantages. Thanks to the precise control of the laser during spot-in-spot aluminum welding, only a small amount of spatter is produced. This results in very good seam quality and visually smooth seams. With long weld seams of 1.5 to 2 m, several battery box assemblies can be joined with virtually no distortion. The low distortion is crucial so that the battery boxes retain their shape after welding and complete battery units are precisely joined together. Aluminum welding of battery boxes offers an efficient, precise and high-quality solution that meets the requirements of the electric vehicle industry.

When laser welding complex body parts in the visible area, such as car doors, the highest demands are placed on the visual appearance of the weld seams. Therefore, particularly smooth seams are required, which can be painted directly without reworking. The diode laser in spot-in-spot configuration used for this purpose works on the one hand with a main spot at high power input and on the other hand with a surrounding spot that smoothes the weld seam in the same operation. The result is a homogeneous weld seam free of pores and spatter, and no further processing of the material is required. Depending on the application, this process can also be used without additional welding wire, which contributes to cost savings in production.

Which laser systems are particularly suitable for aluminum welding? Here you will find a selection.

Then please do not hesitate to contact us.

Your Request