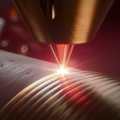

Laser Metal Deposition with Diode Lasers

Laser metal deposition (LMD) generates high-quality claddings and coatings with a lifetime that sometimes even exceeds the durability of galvanic coatings.

Laser metal deposition (LMD) generates high-quality claddings and coatings with a lifetime that sometimes even exceeds the durability of galvanic coatings.

Diode lasers are an ideal tool for every variant of deposition welding. Their fundamental advantages include high flexibility and short processing times, low distortion of treated workpieces as well as fine-grained coatings with excellent adhesion. The extremely hard-wearing surfaces require hardly any reworking. This manufacturing process is especially suitable for applications where laser power and precision are critical. Using advanced laser technology, the process enables high-quality results even for complex structures. There are various reasons why the additional layers might be desired. Every coating, whether for protecting heavily stressed surfaces of metal workpieces from wear and corrosion or repairing high-quality components, can be carried out very effectively with lasers, as can the generative production of complex structures. Additionally, this method is compatible with heat sensitive materials due to the minimal heat affected zone.

Another motivation behind this procedure is to protect surfaces against wear. Here, laser cladding is in competition with thermal spraying, among other options. Since laser deposition welding creates a metallurgical bond between the base material and the additional layer, it achieves a much longer service life than the purely mechanical spraying process. The materials are often Ni-based alloys (In 625) with tungsten carbides. They can amount to up to 60 percent of the applied layer by weight.

Laser coating is very well-suited to preventing creep corrosion, as well as crevice corrosion, with the additional layers. For this purpose, stainless steels and nickel alloys are applied to low-alloy steels. When diode lasers are used as an energy source, the mixing of the materials is at a level of typically less than 5%. As a result, one layer of approx. 1 mm is sufficient for good corrosion protection, while alternative and conventional processes require two layers.

An introduction to laser metal deposition welding (LMD), also known as laser cladding, with an example from our application center. The complete webcast with more examples and further information on laser cladding can also be found in the LIVELINE media library

If you have any questions or would like to learn more about industrial applications and processes relating to laser metal deposition (LMD), do not hesitate to contact us.

A remarkable aspect of the showcased technology is its excellent material deposition rate. By utilizing advanced powder delivery systems, up to 35 kilograms of material can be deposited per hour—setting a global benchmark in high power laser cladding. This capability opens new possibilities for efficiently coating large components or reinforcing structural parts with high-strength alloys. The precise control of layer thickness and uniform powder distribution ensures high quality results that meet the rigorous demands of various industries.

Laser Metal Deposition (LMD) using high power diode lasers delivers substantial advantages in industrial manufacturing. With advanced laser technology, this process enables precise processing of materials such as copper alloys, stainless steel, nickel, and cobalt-based alloys. One of the standout features is the exceptional efficiency of the process: with a powder utilization rate exceeding 95% and homogeneous distribution of material in the melt pool, material waste is minimized, leading to significant cost savings. Thanks to the large spot diameters and optimized powder delivery systems, layer thicknesses of up to 1.5 mm can be achieved with dilution levels below 5%. These characteristics make LMD an ideal solution for applications requiring wear and corrosion protection, such as in the aerospace, automotive, and heavy industries.

The last major area of laser deposition welding is the generation of components, often referred to as additive manufacturing (AM) or 3D printing. Here, too, layers of identical materials are applied. As a result, mixing need not be considered separately. Layer by layer, components with complex structures can also be generated if the processing system is programmed appropriately. In addition to stainless steels, aluminum, titanium and superalloys are increasingly being used here, as they are used in turbines, fuselages and wings in aircraft construction.

Tapping into oil and gas fields requires high-performance drilling tools. These tools are subjected to huge stress and would not reach long lifetimes without wear protection. That is why special coatings, increasingly realized with diode laser cladding, have been the standard for some time now. Laserline’s LDM and LDF diode lasers achieve excellent results in this regard.

In this process, the laser beam melts the wire that is fed in and the material of the component to be coated. Wire with diameters of approx. 0.8 to 1.6 mm is used, which is led to the additive welding process by commercially available wire feeders. Today, it is estimated that 90% of the applications involve being coated with powder and 10% with wire. Areas of application for laser deposition welding with wire include the repair of components and the functionalization of surfaces. The process is particularly economical and clean, and reworking is reduced to a minimum.

In addition to damage to protective coatings, cracks in components can also make repair welding necessary. However, such components are not always easy to reach: Where, for example, the disassembly of a torn gear wheel is not easily possible, in case of doubt the laser must come to the metal of the workpiece. This is no problem with Laserline diode lasers: the lightweight, compact and mobile lasers can even be used on narrow scaffolding at lofty heights and positioned safely if required. This means that all necessary welding work can be supported.

A mobile LDF 3000-60 diode laser system and a robot for control were installed at a height of 25 m to repair cracks in the gears using laser metal deposition welding.

Then please do not hesitate to contact us.

Your Request