Laser Brazing with Diode Lasers

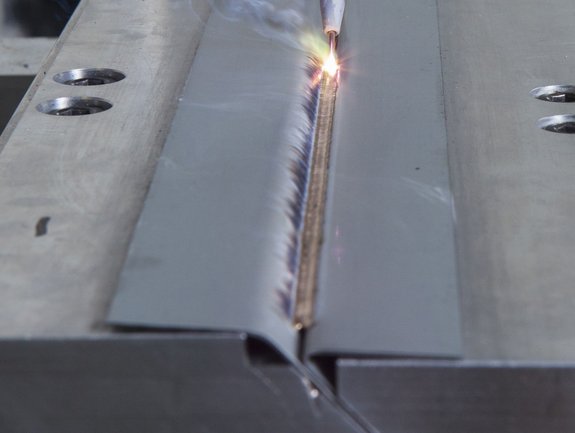

High process speed, low heat input, and smooth, tight and clean brazed seams are the main characteristics of diode laser brazing.

To the examplesHigh process speed, low heat input, and smooth, tight and clean brazed seams are the main characteristics of diode laser brazing.

To the examplesJoining methods, in which the brazing solder is melted by an industrial laser, have mainly been used in the mass production of vehicle bodies. There, laser beam brazing is mostly used for joining galvanized steel sheets or lightweight components made from aluminum, but also for other brazing material. Laser automobile brazing is usually carried out with a brazing optic that is integrated into a robot. The laser beam is guided along the joint where it melts the brazing solder – e.g. a copper-silicon wire – and in so doing, connects the components together. The success of the brazing process depends on whether the firmness is similar to the welding seams and on the high aesthetic quality of the joints: brazing seams that were generated with lasers are known for their sealed, smooth and clean structures. They are visually appealing and reduces post-processing to a minimum. The car body can often be lacquered immediately after cleaning, for example.

The global practical usage of Laserline’s diode lasers has been established in the field of laser brazing. More than 1,000 LDF diode lasers are in successful permanent use for different brazing applications within automotive body assembly around the globe. Besides the requirements of higher firmness and a heat-affected zone that is as small as possible, there are particularly high standards in terms of the appearance of the joint for visible seams. A key process advantage of diode lasers is the strikingly calm melt pools.

The multi-spot module developed by Laserline also achieves enormous process advantages when brazing with triple spot - for example when joining hot dip galvanized sheets in automotive production: when brazing hot dip galvanized sheets, which is often difficult, this technology can achieve the usual high brazing seam quality without reducing the process speed.

In 2018, the triple-spot process won the Innovation Award Laser Technology of the Arbeitskreis Lasertechnik e.V. and the European Laser Institute ELI.

Laser brazing has long since secured a well-established place in terms of the manufacturing of vehicle bodies. However, the increased use of hot-galvanized sheets has led to problems, recently: the number of micro splashes and wavelets has grown, forcing a reduction in process speed. Laserline has developed a ground-breaking solution with its variable multi-spot module, in which side-spots are positioned in front of the main-spot: the pre-spots ablate the galvanizing at the brazing seam and thus calm the brazing process, which can be undertaken at the usual speed, as a result. This is viewed as a trend-setting process.

When galvanized sheets (that is, on an electrolyte basis) are processed as before – people call them “elo-zinc” – brazing diode lasers with the classical single-spot are sufficient. Here, the beam source is mostly integrated into special brazing robots. Thanks to the calm melt pools created by diode lasers, the melting of typical brazing solders based on silver or whitish silver poses no problem at all, resulting in attractive, high-quality seams.