Application Laboratory

It is a key part of our corporate philosophy to realize tailored laser solutions for our customers.

It is a key part of our corporate philosophy to realize tailored laser solutions for our customers.

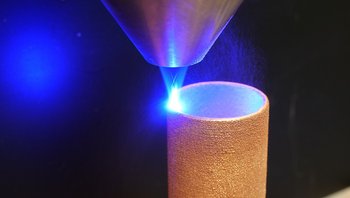

To be able to support you optimally, at our headquarters in Mülheim-Kärlich, close to Koblenz, Germany, we’ve built from scratch a first-class and fully equipped application laboratory. Here, a team of highly qualified and experienced application engineers will take care of the first feasibility studies and advise you on that basis in terms of plant design and selection of suitable beam sources. If needed be, we integrate our worldwide network of experts comprising competent system integrators and representatives of renowned research institutions into solution development. When a sustainable concept is set up, a prototype of the laser system can be created and tested under production-like conditions. The models for mass production will not be finalized let alone finally delivered until it is certain that the system runs as planned.

In this way, step by step and in close coordination with you, a laser solution is developed that is tailored exactly to your individual needs. A major advantage is the modular design of Laserline diode lasers: by this, subcomponents can be combined in different ways, e.g. special spots or optics pose no problem whatsoever.

Would you like to entrust yourself to our development work in the application laboratory and wish to be advised and accompanied along with the conception of your solution? Contact us!

The high-quality equipment of the Laserline application laboratory allows the practical implementation of numerous application details. In this way, production-like application conditions can be realized while the functions of the designed laser system can be reliably tested. In addition to all Laserline beam sources, multiaxial work stations are also available.

Would you like to get advice on the conception of your solution? Feel free to reach out to us!

Your Request