Oil and gas

Diode lasers in the oil and gas industry

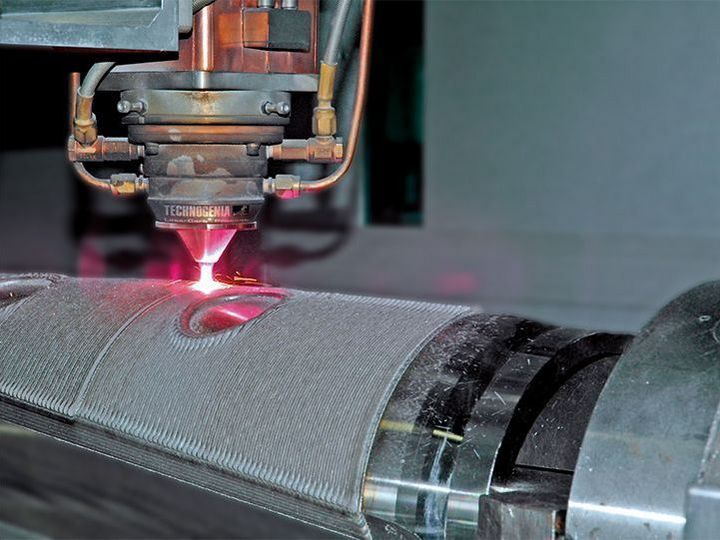

In the oil and gas industry, companies share independently from their segment certain challenges: The use of big tools and systems under difficult operation and environmental conditions. To defy the corrosiveness of crude oil and natural gas, the inner coatings of oil and gas tanks must be stable long-term and additionally pore-free and crack-free to ensure the required safety. Coatings by laser-based powder cladding can be fairly convincing here by their maximal impermeability combined with a long lifetime, which is why they are clearly superior to other coating techniques such as thermal spraying.

Furthermore, the relatively new high-speed powder cladding (and high-speed-cladding) allow for a quicker realization of large-scale coatings and a more economical process control. Additionally, it can replace galvanic coating processes like (threatened by an EU-wide prohibition) hard chromium plating and therefore is also interesting for the realization of protective coatings of drilling tools that are exposed to particularly great wear and strong corrosion.

A further field of use for Laserline's diode lasers is, for example, the tape winding of seamless tubes out of fiber composite materials for off-shore areas. With customer-individual homogenization optics that can be integrated into the head of a tape laying robot, process speeds of several meters per minute become possible.