Optics for Welding

Heat conduction and keyhole welding of metals and non-metals

Heat conduction and keyhole welding of metals and non-metals

Laserline’s welding optics can be configured flexibly and can therefore be adjusted to different process requirements and boundary conditions. Furthermore, the optics are optimally adjusted to Laserline's diode lasers and therefore allow for process results that meet the highest quality demands. Additionally, in case of difficult process conditions, sensors for seam tracking or process monitoring can be integrated.

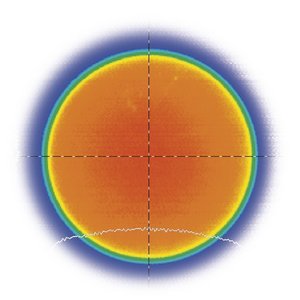

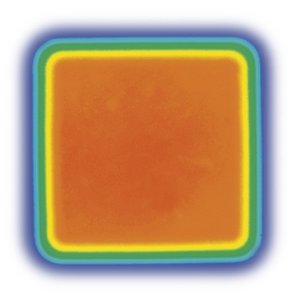

Diode lasers optimize heat conduction welding in several ways. The even power output and homogeneous intensity distribution of the top-hat beam profile guarantee excellent seam quality and high process stability.

Do you have any questions about our processing optics?

Please feel free to contact us!