Joining in the Car Body

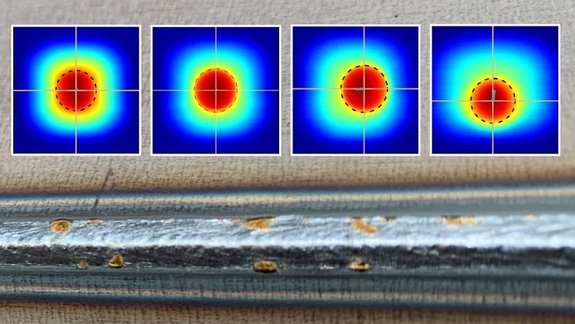

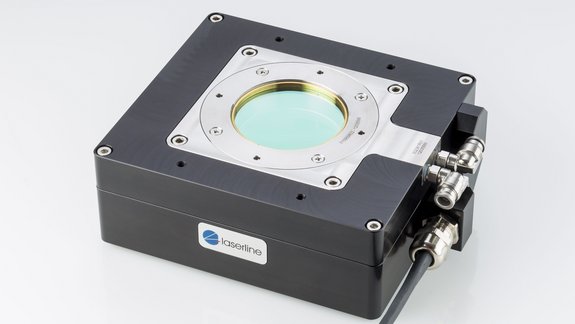

The highest requirements for the optical appeal of the seam are on the outer skin. Typical applications are the laser welding of aluminum or laser brazing of galvanized sheets in tailgates as well as the roof/sidewall connection. In these applications, Laserline is also leading in the process development, and offers tailored multi-spot modules for optimizing the respective process.

In the structures, doors, door cutouts, as well as in A-, B- and C-pillars, diode lasers are used for laser beam welding. For remote welding, diode lasers with a beam converter are used.

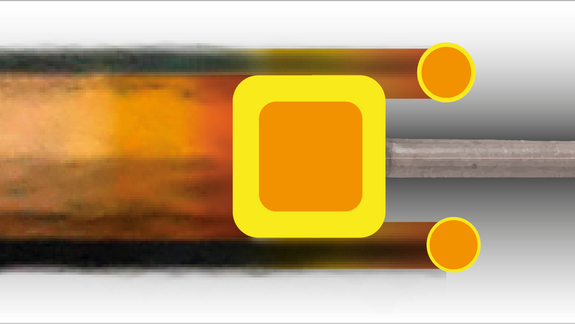

As to tailored-blanks welding, sheets with different material thicknesses are joined, and thus tailored blanks for the metal-forming pressing of car body components are created.

Furthermore, diode lasers are used in the drive train for the welding of gearwheels for hardening cam and crankshafts, as well as for hardening and coating of pressing tools.

Applications in the Manufacture of Electric Vehicles

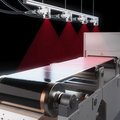

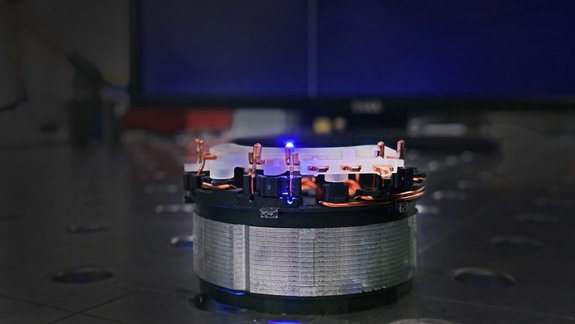

Significantly more electronic components are used in electric vehicles than in conventional vehicles. Copper welding with blue diode lasers allows copper pins and sheets to be welded to small motors or battery contacts, for example. Another important application is the laser drying of battery foils with large laser spots. The aluminum welding of large battery boxes covers another application in electric cars.