Applications

Drying with diode lasers is a cost-efficient and environmentally friendly alternative to the widely used convective oven drying. With homogeneous area spots, even large surfaces with side lenghts of up to 2 m can be irradiated. In principle, all materials that exhibit sufficient absorption for the laser wavelength can be dried. The laser beam heats only the coating, thus yielding a targeted evaporation of the solvent or even sintering on the workpiece. The spectral range of the laser radiation used is either in the near infrared range (NIR), more precisely between about 900 and 1070 nm, or around 445 nm in the case of blue diodes. Due to the ease of integration into existing machine concepts, fiber-guided high-power diode laser systems of 1-50 kW output power are generally used.

Application examples

The semiconductor-based direct conversion of mains power into laser radiation functions independently of fossil fuels and also provides pinpoint energy use in the process. Laser drying significantly reduces the space required for the production environment and enables faster process speeds with more energy-efficient process control. In particular for the production of lithium-ion batteries, Laserline diode lasers are ideally suited to drying of the electrode paste (slurry). This is an efficient alternative to gas-based convection ovens and high-maintenance infrared lamps.

You can find more detailed information on this topic in our journal article or in our IDEEL press release.

Energy and quality turnaround for drying processes

Replacing convective drying with laser drying? In times when highly efficient electrified solutions are sought in the face of gas shortages and rising energy costs, this could become the standard. Diode-laser-based drying processes in roll-to-roll mode, optimized by a revolutionary beam shaping technology, bring excellent throughput rates and results as well as making a significant contribution to gas phase-out and climate protection.

The IDEEL research project aims to launch a laser drying process for the more climate-friendly and economical series production of lithium-ion batteries. In this context, laser-dried anodes and LFP cathodes have now been successfully produced for the first time using a roll-to-roll process. The innovative manufacturing process significantly reduces energy consumption in electrode production while doubling the drying speed.

Fuel cell and electrolysis systems are at the forefront of clean energy technology, featuring intricate multilayer structures with electrodes and membranes - often requiring hundreds for each system. The challenge lies in scaling up production speed at low machine footprint and high efficiency, and laser drying emerges as a transformative solution.

Our cutting-edge laser drying technology is providing a new energy efficient fuel cell manufacturing, addressing various production stages where traditional drying ovens are currently employed. From different substrates and separators to the application of specific coatings like Catalyst Coated Membrane (CCM), our laser system seamlessly integrates into the entire production process where heat treatment is required.

Laser drying offers direct coupling of radiation into the target layer with high spatial definition, ensuring precision and high heating rates.

With a Laserline diode laser boasting over 52% wall plug efficiency, our laser drying system is one of the most efficient solution in fuel cell production.

The laser system incorporates optimized heat management with possible closed-loop control and millisecond response time, ensuring a controlled and efficient drying process.

Laser drying acts as a crucial enabler for scaling up serial production with more compact dryers, reducing the overall machine footprint and increasing production speed.

The efficiency and feasibility of the laser drying process depend on the absorption coefficient of the substrate, ensuring optimum performance tailored to the material in question.

Laser drying is adaptable to various heat treatment and drying steps, including Roll to Roll or continuous processing, making it a versatile solution for different fuel cell components such as gas diffusion layers or proton exchange membranes.

All the laser energy is closely focused into the target layer, prohibition inefficient heating of the surroundings. Because the direct absorption of the energy in the target layer, no surrounding areas are heated.

Fuel cells are recognized as the building blocks of future technology, and laser drying emerges as a critical enabler for scaling up productivity in the most compact and efficient drying ovens.

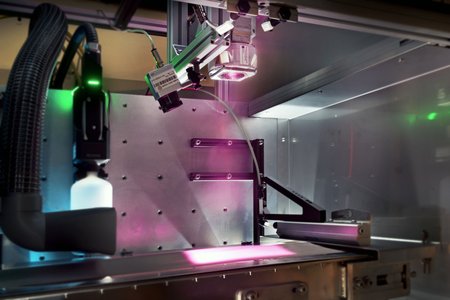

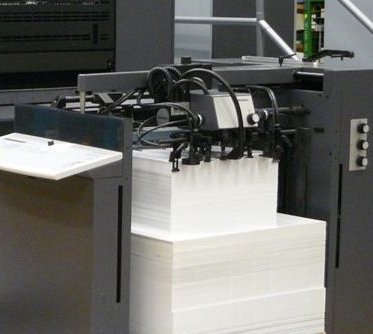

An optimal laser drying of offset color layers requires the direct integration of the beam source into the printing system. This is the only way to achieve a possibly effective drying and thus an efficient process control. For this, the laser head, supply unit, as well as the necessary homogenizers and line focus optics have to be integrated exactly into the given assembly space. This requires compact, individually suitable components. The diode lasers and optics of Laserline meet these demands in an optimal way: their modular and compact design makes it possible to tailor all components precisely to the individual customer’s needs. Power compromises do not need to be accepted. Despite their highly compact design, Laserline's diode lasers can easily provide powers in the double-digit kilowatt range.

Which laser systems are particularly suitable for drying? Here you will find a selection.