Technology Partnership & Customized Laser Systems

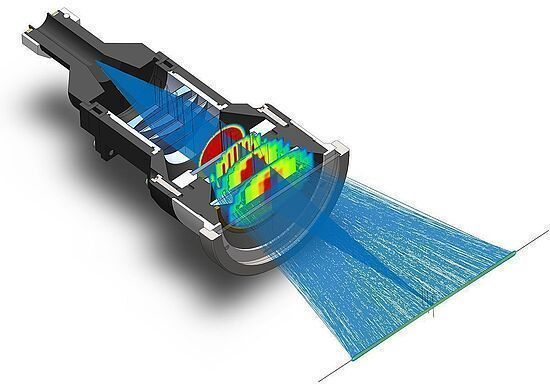

Individual laser systems including direct, non-fiber-coupled diode lasers as pump or light sources and beam shaping.

Individual laser systems including direct, non-fiber-coupled diode lasers as pump or light sources and beam shaping.

Laserline is the right partner when conventional technologies reach their limits. When new approaches are sought to solve problems and when complex processes need to be made more efficient. Accepting challenges, driving innovation and designing individual solutions - all this is in Laserline's DNA.

The development of customized laser systems is one of Laserline's core competencies. Driven by our passion for innovation, we have made it our mission to develop tailored solutions for every application scenario and turn technological visions into reality. What sets us apart? Thanks to our many years of experience in a wide range of technology fields, we recognize the potential of new approaches and are not afraid to tackle unusual topics. As a medium-sized company, we are also extremely agile and can react flexibly to requests and challenges at any time. This makes us a reliable partner for the development and production of individual laser systems that go beyond the standard.

When developing individual solutions, the modular design and high degree of innovation of our systems and optics prove to be a key strength. Depending on the task at hand, elements of the laser systems can be recombined, components integrated or completely new modules and systems designed. In this way, all components, from multi-diode laser systems, pump and light sources to application-specific optics can be flexibly adapted to a wide range of requirements. Quality and reliability of the solution are our top priority. This is why every prototype is thoroughly tested in our in-house application laboratory under production-like conditions and subjected to comprehensive qualification tests before being used in the field. In this way, we ensure that the new laser system meets all requirements and quality standards perfectly.

For us, innovation and standardization are two sides of the same coin. We transform pioneering approaches into standardized solutions so that they can be used on a broad scale - and these standardized solutions in turn form the basis for future innovations. Your customized approach is therefore always based on a product that has already proven itself in practice - and may even turn into series production in the future.

You don't know how to optimize the joining, hardening or cladding of materials? Is a standard laser system no longer sufficient for your requirements? Or do you already have an idea for a completely new approach and are looking for a way to technically implement your vision? No matter where you are: We pick you up right there and work closely with you step by step to develop customized solutions that are precisely tailored to your individual requirements.

Rotating high-power diode lasers? The approach sounds unusual, but it can significantly increase production capacity in tape winding for the manufacture of endless tubes. Laserline has developed a globally unique rotating multi-kW diode laser specifically for this application. In this process, several compact direct diode lasers rotate around the longitudinal axis of the tube on a rotating device and weld tapes while the tube is moved back and forth. Parallel processing increases process speed and production capacity, making economical large-scale production possible for the first time in the field of tape winding.

Whether in cooperation with customers, partner companies or research institutes: We have been involved in pioneering research projects for years in order to actively shape the future of laser technology. Our aim is to transform original scientific ideas into concrete solutions and marketable products and to drive forward general research into new technologies and areas of application for high-power diode lasers.

The research project IDEEL aims to launch a laser drying process for the more climate-friendly and economical series production of lithium-ion batteries. In this context, laser-dried anodes and LFP cathodes have now been successfully produced for the first time using a roll-to-roll process. The innovative manufacturing process significantly reduces energy consumption in electrode production while doubling the drying speed.

As part of a research project called FoulLas, Laserline, the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) and the Laser Center Hannover are tackling marine fouling on underwater surfaces. Instead of conventional mechanical removal, the so-called biofouling is combated in this series of experiments by underwater irradiation using lasers. The aim is to use the cell-damaging effect of the blue laser light from an LDMblue diode laser to damage the cell structures of the colonized marine organisms to such an extent that the fouling is washed away by the current. The approach is currently being tested in a real laboratory.

Diode lasers in lighting technology - before their further development into industrial lasers in the mid-1990s, diode lasers were already being used to create stage lighting effects. Today, around two and a half decades later, they are returning to their origins and are now opening up completely new possibilities with output powers in the multi-kilowatt range. For example, an innovative approach to generating high-power white light of over 100,000 lumens using blue diode lasers and rotating phosphor converters is currently being tested in Laserline's application laboratory.

Strong companies need strong partners. That is why we rely on close and trusting cooperation with other companies, which we usually support for years in the realization of various projects. Our technology partners include major international corporations such as Audi, Volkswagen and KLA, as well as regional hidden champions such as ALOtec. Together, we implement innovative ideas and develop new solutions for a wide range of problems.

Laserline high-power diode lasers in various performance classes and configurations have been successfully used in KLA system solutions for the optoelectrical testing of wafers for many years. The Supplier Excellence Awards were presented by KLA to Laserline and two other suppliers in 2019 for demonstrating outstanding performance in their respective categories in the areas of technology, quality, responsiveness, delivery and cost. We are proud to receive this special award from one of our key business partners in the electronics industry.

KLA develops industry-leading equipment and services that enable innovation across the electronics industry. This includes advanced process control and process solutions for the manufacture of wafers and reticles, integrated circuits, packaging, printed circuit boards and flat panel displays.

Integration into a wood processing machine: A pioneering option for using diode lasers in laser edging is the integration of lasers and zoom optics into a wood processing machine. Thanks to the modular design of the Laserline beam sources and zoom optics, highly variable customer-specific adaptations are possible here. The optics are equipped with motorized lens systems and enable precise automated adjustment of the line focus. Thanks to the technically and economically optimized process control, batch size 1 production is also economically feasible with the corresponding wood processing machines. IMA Klessmann has been successfully using fiber-coupled LDM diode lasers for edging with laser technology since 2010.

Do you have any questions about our customized solutions? Please feel free to contact us!

Your Request