Optics for Cladding

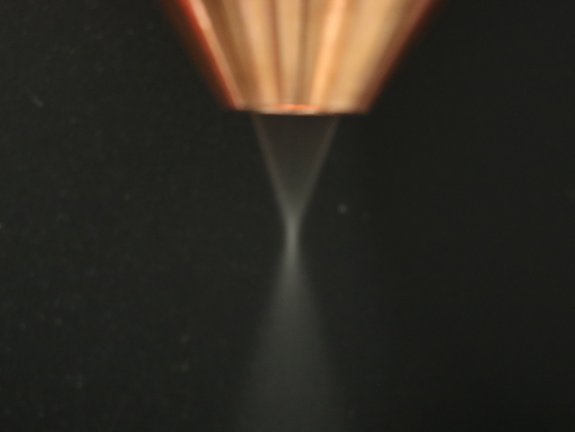

Optics for cladding, repair welding and additive manufacturing of metal components. Special powder nozzles as well as optics monitoring and process control as adapted modules.

Optics for cladding, repair welding and additive manufacturing of metal components. Special powder nozzles as well as optics monitoring and process control as adapted modules.

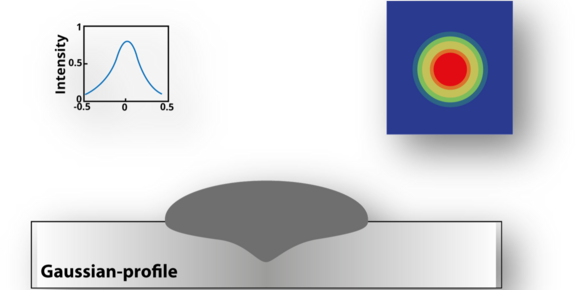

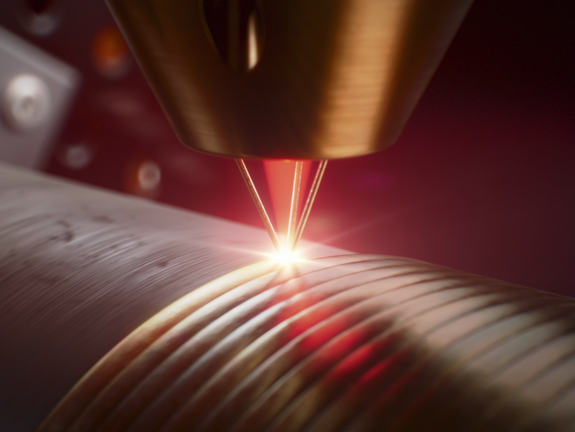

In the great selection of Laserline cladding optics for every application, a suitable tool can be found. For cladding, repair welding or additive manufacturing, different powder nozzles can be combined with the modular optic system from Laserline. Because of the various configuration possibilities, the process optic can be flexibly adjusted to different process requirements and boundary conditions. Furthermore, all available modules are optimally adjusted to Laserline's diode lasers, and therefore allow for process results that meet the highest quality demands.

The OTS-5 MultiWire Optic is the new tool for wire cladding with up to three wires applications like cylinder cladding, tube cladding and more.

The new OTI processing optics enable high-performance laser cladding on internal surfaces and hard-to-reach areas. Combined with high-power diode lasers, they deliver efficient and precise coatings, and enable immersion depths of several meters. Ideal for applications beyond the reach of conventional tools, OTI optics make previously inaccessible surfaces fully coatable.

New cladding technologies enable the production of low-wear brake discs and lead to a significant reduction in particulate emissions. Today's gray cast iron brake discs already have a good service life, but are subject to wear and tear and have to be replaced several times over the course of a vehicle's service life.

Do you have questions or a specific task?

Please feel free to contact us!