Automated Tape Laying

Production of high-quality and cost-effective glass fiber and carbon fiber composite components is made possible by automated tape laying & winding in industrial production.

To the examplesProduction of high-quality and cost-effective glass fiber and carbon fiber composite components is made possible by automated tape laying & winding in industrial production.

To the examplesThe tapes are unidirectional, continuous thermoplastic filaments that are partially pre-impregnated with adhesive resin. Like a tape, they are rolled onto a reel, and this is how they are integrated into the manufacturing system. The system’s feed unit draws the tape from the roll and a robot places it on the work platform or the semi-finished component in the required position. There, it is heated with a laser, which melts the adhesive and increases its grip. Step by step, this enables precisely contoured continuous filament structures to be created with a high level of rigidity through automated fiber placement.

The fields of application for Laserline beam sources which were tapped into at an early stage include industrial systems for the tape laying and tape winding of fiber-reinforced plastics. Here, the tapes that are laid down or wound are welded by means of high-power diode lasers. These processes are used in the automotive and aircraft industries, among others, as well as in the production of seamless tubes, for example, for offshore applications.

The biggest advantages of Laserline’s diode lasers lie in the homogeneous distribution of intensity in their focus, which can even be optimized with special optics, and their precise temperature regulation, which enables controlled melting to be carried out. Together, they allow the component to be manufactured directly, thus speeding up the process of tape laying significantly.

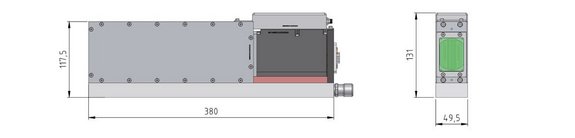

An ultra-compact direct diode laser for heat treatment applications, with a housing width of only 50 mm. The processing head with integrated beam source and optic generates rectangular, fully homogenized laser spots that can be adapted to the process requirements. Multiple processing heads can be cascaded to form a system setup.

Diode lasers have been used in the manufacture of CFRP components since 2009. For the tape-laying and tape-winding of fiber-reinforced plastics, the tapes that have been laid down or wound are welded using lasers. The improved mechanical properties of the products and weight savings of up to 70 percent are leading to a continuous increase in the applications involving CFRP (carbon fiber-reinforced plastic) components. However, current production systems using a single machining head have a limited maximum yield. In order to increase the production capacity of tape application systems, Laserline developed a modular direct diode laser with a housing width of less than 50 mm. The design allows several heads to be integrated into one clamping. The processing head, with an integrated laser source and optic, generates a rectangular, fully homogenized laser beam that can be adapted to the tape sizes in question. The maximum laser power of more than 2 kW per processing head ensures high process speeds and guarantees that the tape material will melt reliably. A high working distance of more than 200 mm enables production to be both contamination-free and collision-free. The use of nothing but industry-proven standard components makes certain that processes can be started up swiftly and reliably.

For the tape winding of pipes, the thermoplastic band is laid around a preform and melted. The process requires quick, precisely controlled heat input (in terms of the exposure area and exposure time). This goal can be achieved on a reliable basis thanks to Laserline’s diode lasers. Homogenization optics, individualized for each customer, that can be integrated into the head of a tape laying robot, as well coaxial multi-point temperature regulations, guarantee that the material is heated gently. Tape winding on the basis of diode lasers can achieve process speeds of several meters per minute and works with just about any component geometries.

Since 2009, Laserline’s diode lasers have been used by AFPT GmbH for manufacturing CFK series components. With special homogenization optics, it is possible to attain tape laying speeds of several meters per minute, reaching a very good level of process efficiency.

Besides tape-laying and tape-winding of fiber-reinforced plastics, the laser-based irradiation of the nip point is used as well in other roll-to-roll or calendering applications. For the application of dry coating on battery electrodes, a polymer compound with carbon particles must be locally heated and compressed in order to consolidate the electrode layer on a thin substrate. The state of the art dry coating machines apply heat conduction rollers, which are limiting the process speed by the heat transfer from the heated rollers which acts mainly during a line contact in the nib point. In contrast to the limited heat conduction by rollers, the local heating by laser allows a homogeneous and rapid heating prior and also directly in the nip point. Due to the very high intensities enabled by laser, an acceleration of the processing speed beyond current state of the art machine by multiple factors is possible.

Which laser systems are particularly suitable for tape laying of fiber-reinforced plastics? Here you will find a selection.

We will be happy to answer your questions about lasers for automated taping!

Your contact