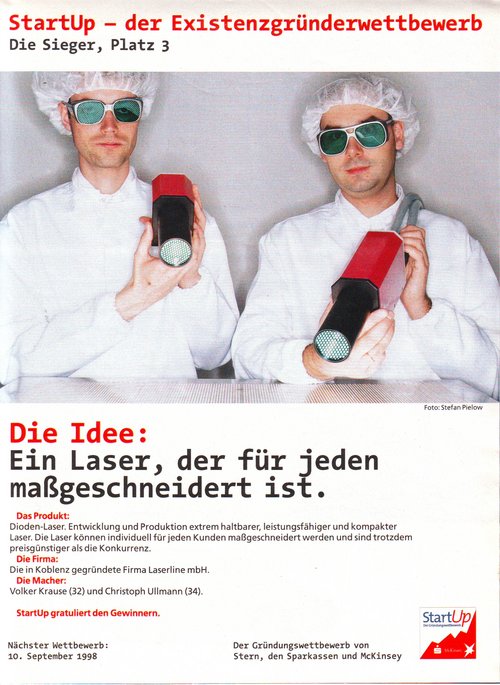

25 Years of Laserline – A Brief Profile

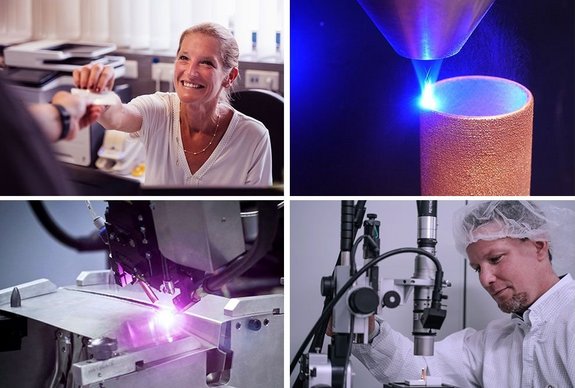

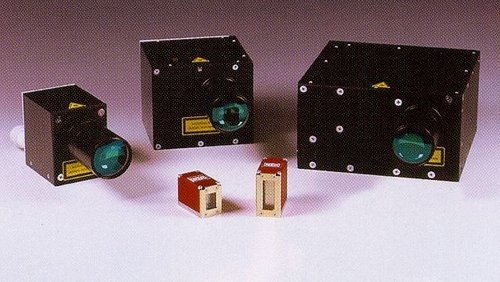

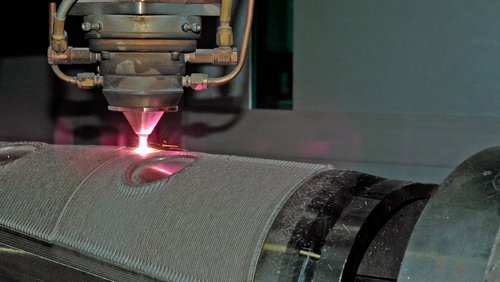

What began as a small team at the Koblenz Technology Centre has now become the embodiment of industrial laser technology itself. Since 2002, Laserline has been located at its own approx. 15,000 m² premises in Mülheim-Kärlich, Germany, with production in state-of-the-art production plants, thinkers in innovative development laboratories, and eight international subsidiary laser manufacturers in USA, Mexico, Brazil, India, Japan, China, and South Korea, all the while working with distribution partners in Europe (France, Italy, Great Britain) and in the Asia-Pacific region (Singapore, Taiwan, Australia). Today, Laserline has more than 400 employees.