blue | Blue Diode Laser

Diode laser for the processing of highly reflective metals such as copper or gold in a new power class of up to 6 kW laser power

Overview of application areasDiode laser for the processing of highly reflective metals such as copper or gold in a new power class of up to 6 kW laser power

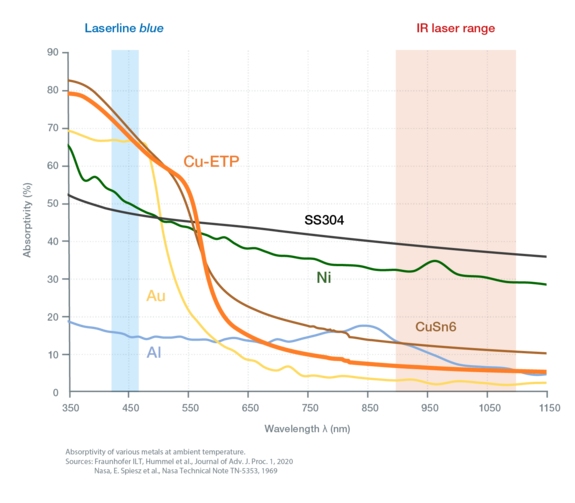

Overview of application areasLow energy absorption of highly reflective metals such as copper or gold in the 1,000 nm wavelength range poses major challenges for standard IR lasers. The required high initial intensities induce processes often characterized by turbulent melt pools and spatter formation, that are critical factors in the processing of electrical components.

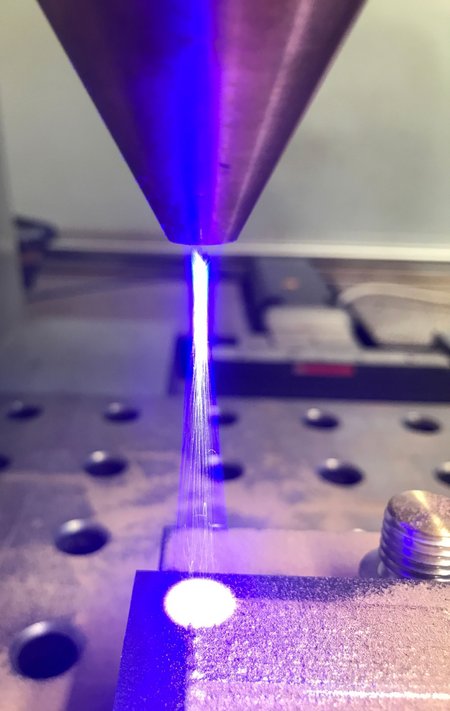

Laserline’s blue high power diode laser series revolutionizes the processing of copper, gold and its alloys in various ways. With approximately 445 nm, these lasers offer the ideal wavelength for the laser processing of highly reflective metals. Multiple times higher absorption allows significantly lower intensities and larger laser spots. Diode lasers achieve a smooth, stable and simple process that leads to a reproducible result without spattering.

Over the past two years, Deutsches Elektronen-Synchrotron DESY in Hamburg has conducted extensive welding tests to illustrate the behavior of the melt pool conditions. Through high-frequency X-rays, the cross-section of the melt pool has been made visible, providing invaluable insights into the welding process and the melt pool dynamics.

Identical laser power and weld speed

The results highlight the outstanding performance of our blue diode laser, exhibiting stable melt pools without turbulences or pore formation while maintaining a consistent weld depth. In contrast, infrared lasers, requiring smaller spots for coupling with copper surfaces, demonstrate inferior welding depth, accompanied by higher turbulence and pore formation.

Available as stand-alone devices (LDF) or 19" rack Laser (LDM) ready for integration. More technical specifications

The blue diode laser revolutionizes the processing of copper, gold, and other highly reflective metals in several ways respects. The direct generation of up to 6 kW (cw) laser power in the 445 nm wavelength range is unique for industrial lasers and also avoids the detour via complex and inefficient wavelength conversions. At the same time, absorption and thus process efficiency are increased significantly compared to IR lasers. The precisely controllable energy deposition of the diode laser enables copper to be melted without evaporation, resulting in previously unattainable stability of the melt pool. This creates new application possibilities, such as heat conduction welding of thin copper foils or spatter-free welding processes of electrical connectors.

| Max. output power* | 800 W | 1,800 W | 2,000 W | 2,000 W | 5,000 W | 6,000 W | |||

|---|---|---|---|---|---|---|---|---|---|

| Beam quality | 20 mm.mrad | 30 mm.mrad | 60 mm.mrad | 20 mm.mrad | 30 mm.mrad | 60 mm.mrad | |||

| Other laser powers and process-adapted beam qualities available | |||||||||

| Optical fiber | 400 µm [NA 0.1] | 600 µm [NA 0.1] | 600 µm [NA 0.2] | 400 µm [NA 0.1] | 600 µm [NA 0.1] | 600 µm [NA 0.2] | |||

| Fiber length | Fiber lengths of up to 20 m | ||||||||

| Wavelenth range | 445 nm ± 20 nm | ||||||||

| Product series | LDMblue | LDFblue | |||||||

*Power specification for fiber length of 5 m.

Any questions on our blue lasers or industry applications with blue laser light?

Please send us your request!

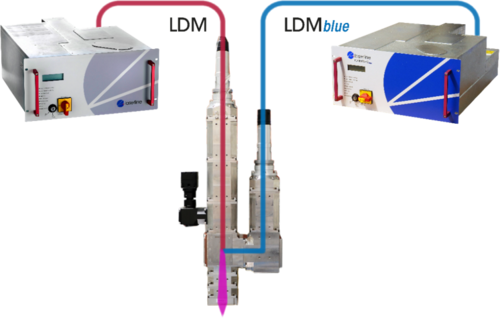

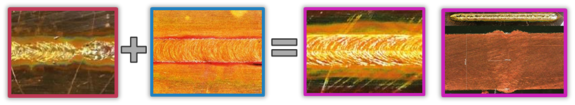

Combining the blue laser radiation from LDMblue with a laser in the infrared wavelength range leads to highly stable, almost spatter-free keyhole welding processes. The blue laser stabilizes the process, even when welding in deep penetration mode, while the NIR laser provides the additional energy. Laserline has developed special hybrid optics that combine the blue and NIR laser beams.

In 2018, blue diode lasers were available for the first time. As part of the EffiLAS (Efficient High Power Laser Beam Sources) funding program launched by the German Federal Ministry of Education and Research (BMBF), for the first time a blue kilowatt diode laser has been built and optimized for materials processing. The globally unique development enables a new segment in laser technology: the processing of materials with laser radiation in the visible wavelength range.

Infrared lasers achieve excellent results in many industrial applications. However, the infrared beam is less suited for processing of nonferrous metals, especially copper. One major reason for this is the low absorption of the laser beam by non-ferrous metals in this wavelength range. As a result, welding processes often run unstably and resulting welding defects in production lead to rejects. The use of blue light with a short wavelength of 450 nm is ideal for attaining a high absorption rate. The much higher absorption enables high-quality and consistent welding results when laser processing copper. The availability of the blue laser beam opens up new fields of application, not just for the laser processing of nonferrous metals like copper or gold, but also for the joining of different metals.

Especially in the field of regenerative energies and alternative drives, there is new potential for the use of blue lasers in production. For example, around eight kilograms more copper is processed during the manufacturing of electric cars than of in cars with combustion engines. This is a small value, but all told, it offers a wide range of possible applications for blue lasers. For instance, in the manufacture of batteries, copper foils with a thickness of ten micrometers are joined together or joined with other metals. For the first time this procedure is possible by the using blue high-power diode lasers.

Significantly more copper is needed in the construction of wind turbines. Large offshore wind turbines use up to 30 tons of copper – here, too, the use of the laser is conceivable in the future. Due to the high seam quality, the process is also extremely well-suited for applications in electrical engineering – especially in the manufacture of components in power electronics, where the joints must be particularly temperature-resistant.

In addition to electronic applications, the new wavelength of the blue laser also enables gold to be processed, leading to new applications in jewelry production. As technical development progresses, numerous other applications are expected to be tapped into in the near future – continuing the rapid technological innovation of high-power diode lasers for industrial production in this new wavelength range.