Laser Cladding

Pore-free and crack-free layers with a long lifetime, high surface quality and exceptional durability.

To the examplesPore-free and crack-free layers with a long lifetime, high surface quality and exceptional durability.

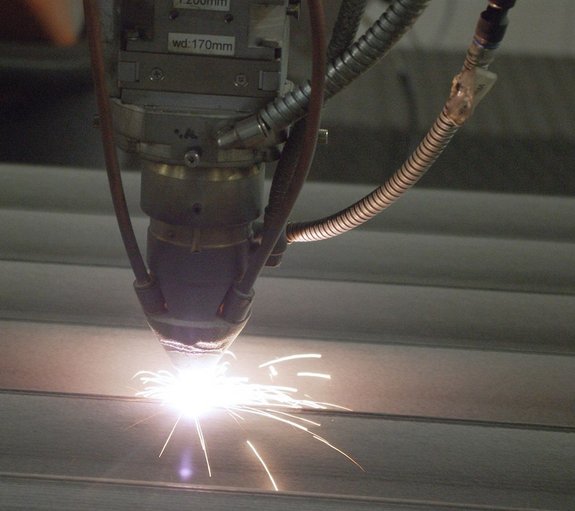

To the examplesThe laser cladding process involves using either wire or powder as coating material, which is melted by a focused laser beam to form a molten pool on the surface of the workpiece. As the material solidifies, it creates dense, metallurgically bonded layers that offer superior durability compared to coatings created by thermal spraying, and pose fewer health risks than conventional hard chromium plating.

Laser cladding with powder

One of the key advantages of laser cladding is the precise energy input provided by diode lasers. Their top-hat beam profile ensures a uniformly heated molten pool, resulting in fine-grained, pore-free, and crack-free coatings. This reduces the need for post-processing to a minimum. When integrated into systems for Extreme High-Speed Laser Cladding, these diode lasers can also deposit ultra-thin coatings that previously required hard chrome plating.

Diode lasers for laser cladding technology are used for corrosion and wear protection in a wide variety of areas: in agriculture and forestry, in mines, offshore, in power plants, and wherever coatings corrode quickly in the local atmosphere or are subject to increased wear. Laser-coated brake discs, for example, lead to a significant reduction in fine dust emissions and provide better protection against corrosion.

Powder-based laser cladding technology using metallic powder reduces both energy and material consumption, making it an ideal solution for coating plain bearings. The process allows the use of multiple materials depending on application requirements. Our customer, ADMOS in Berlin, shares their positive experience after adopting this process. Learn more in the informative video.

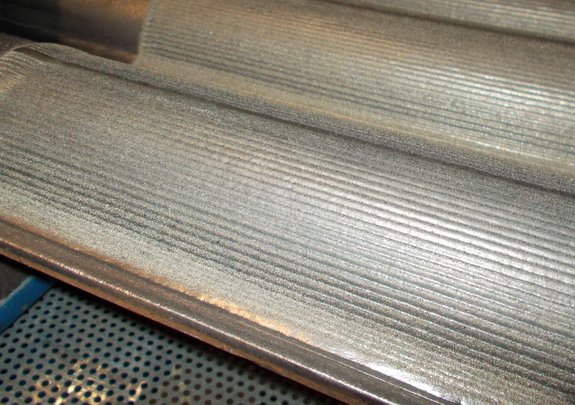

Laser cladding has become an essential and future-proof solution for coating plain bearings. Compared to conventional coating processes, users report significantly higher bonding strength – while reducing material usage by over 70% and energy consumption by around 90%. Especially with bronze and tin-based laser cladding materials, diode lasers deliver excellent results: high precision, minimal cracking, and outstanding emergency dry-running properties, which are crucial for components like wind turbines during start-up.

Beyond conventional cylindrical bearings, even flat or complex geometries can now be economically coated. Thanks to the high process stability, flexibility, and consistent quality of laser cladding techniques, the technology is becoming the new standard in industrial series production. In addition, the process allows precise control over the material properties of the resulting coating, ensuring optimal performance under demanding conditions.

The friction between the brake disc and brake pad generates fine dust, which makes up a relevant proportion of the total fine dust pollution. New laser cladding techniques enable the production of low-wear brake discs with significantly reduced particulate emissions. During the cladding process, an additional layer on the base material – made of tungsten carbide, for example – achieves high abrasion resistance and enables the particularly economical production of a new generation of brake discs. These improvements in material properties contribute directly to longer component life and improved environmental performance. The precision of the laser light used ensures minimal distortion and excellent coating consistency.

The development of oil and gas fields requires high-performing drilling tools. These are subjected to huge stress and would not reach long lifetimes without protective coating. That is why special coatings, now frequently applied using cladding processes, have become the industry standard. Here, Laserline’s LDM and LDF diode lasers have achieved outstanding results: excellent adhesion, high precision, almost no porosity, limited crack formation, a high degree of hardness, and low deformation. In most cases, the created surface does not require any further mechanical processing. In comparison, conventional coating processes such as plasma powder cladding do not attain sufficiently long lifetimes.

An important factor in this application is the control of process parameters, which determine the quality and depth of the applied coating, including the size of the heat affected zone – the area of the base material altered by thermal input.

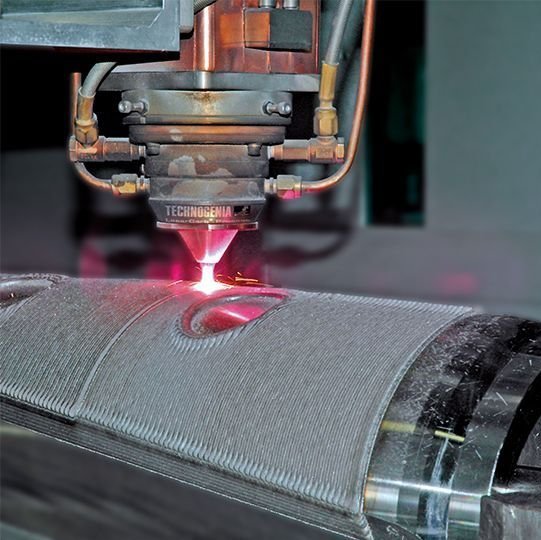

For customers engaged in oil extraction, mining, metal and paper industries, Technolgenia coats components using a stream of metallic powder and Laserline's diode laser systems.

The typical carbide layers that protect saw-blades, disc harrows or counter blades against wear and corrosion can be optimally realized with the help of diode lasers. Distortion and mixing are kept particularly low by a quiet melt pool and minimal heat input. Coating thicknesses as well as track widths can be variably and specifically built up. Oversizes during coating are kept to a minimum, so that the economic efficiency combined with the technical advantages make a strong team for agricultural components. These benefits are further enhanced by the high corrosion resistance of the deposited material, which is precisely controlled throughout the laser cladding process.

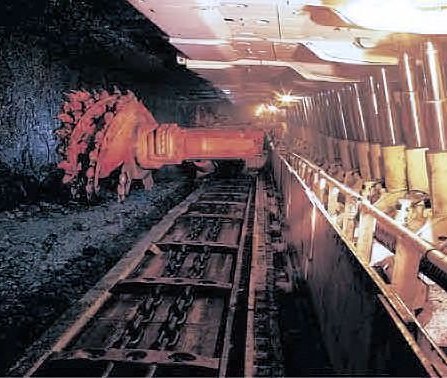

A growing market is laser coating of hydraulic cylinders in technical mining facilities, for example coal extraction. The coating of the cylinder corrodes very quickly under the local atmosphere, which leads to leakage – making replacement or new coating necessary. Until now, chrome plating was the primary method, but it is increasingly being replaced by laser coatings due to their superior durability and process efficiency. The specific increase in durability can’t be quantified yet; however, current results show an increase in the lifetime of more than 100%. The flexible process of laser cladding also allows for tailored coating thicknesses and rapid adaptation to different cylinder dimensions and wear requirements.

The main motivation is the protection against highly corrosive gases or liquids which come into contact with the metal heat exchanger and negatively affect its life cycle. Therefore, nickel alloys with low hardness properties are mostly used, which avoids cracking and can be applied up to 1 mm thickness. Even at high temperatures, they lead to better wear protection and corrosion resistance against aggressive media. Deposition rates of 8 kg/h are possible.

Chlorine attacks metal – a fact well known to operators of biomass facilities and incineration plants. The boiler walls of such plants consist of water-bearing steel pipe systems that absorb thermal energy and transfer it to the water-steam circuit. However, chlorine in the flue gas aggressively breaks down the pipes. Untreated, they are often unusable after only one year.

Meanwhile, many plant operators rely on anti-corrosion coatings. This investment pays off as soon as the operating time is doubled — and more is possible: depending on the applied coating and physico-chemical load, even a tripling or quadrupling of the lifespan is achievable. By using layered structures with a material gradient, the coatings can be optimized for both mechanical and chemical resistance while maintaining coating integrity even under extreme conditions.

Which laser systems are particularly suitable for laser cladding? Here you will find a selection.