Inner Diameter Laser Cladding

High-performance coatings on internal surfaces and hard-to-reach areas, maximum flexibility with high deposition rates

To the examplesHigh-performance coatings on internal surfaces and hard-to-reach areas, maximum flexibility with high deposition rates

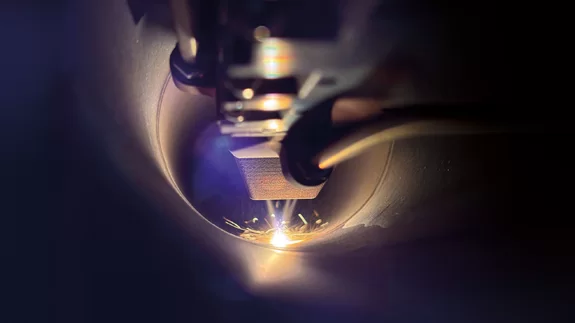

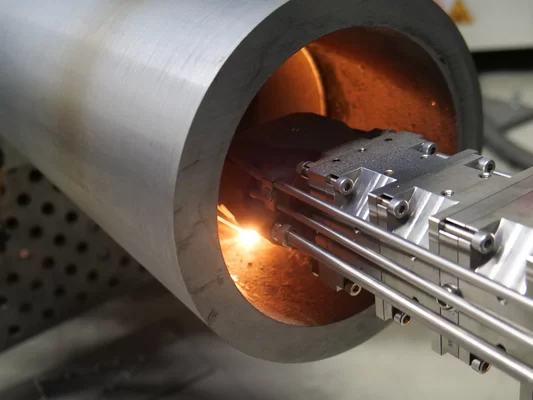

To the examplesInternal diameter (ID) laser cladding is performed using specially developed Laserline OTI processing optics. The laser beam is precisely guided through the optics into the component’s interior, where it creates a molten pool on the inner surface. At the same time, a metallic powder material is continuously supplied to the molten pool and fused with the base material to form a dense, metallurgically bonded coating. Thanks to the compact design and angled beam guidance of the OTI optics, uniform and reproducible coatings can be achieved even at large immersion depths of internal geometries such as pipes, cylinders or plain bearings. The OTI optics also enable the coating of complex geometries, such as those found in truck brake discs. The result is a high-quality, wear- and corrosion-resistant layer with excellent adhesion and surface homogeneity.

Laser cladding with powder

ID laser cladding offers a highly efficient and reliable method for protecting internal surfaces against wear, corrosion, and high thermal or mechanical loads. Using high-power diode lasers in combination with Laserline’s OTI processing optics, this technology enables precise and reproducible coatings even deep inside cylindrical components.

Internal surfaces often face harsh chemical or mechanical stress but are difficult to coat due to limited accessibility. Laser cladding offers durable, metallurgically bonded coatings with tailored materials to extend service life. With OTI processing optics, internal coatings are possible even at depths of several meters - ideal for extruder housings, pipelines, tanks, pressure accumulators, sliding bearings, and more.

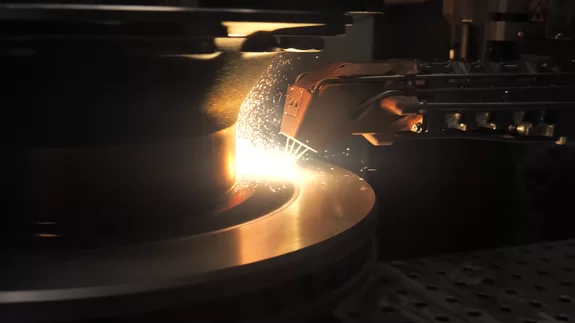

The upcoming Euro 7 regulations aim to reduce particulate emissions and thereby improve public health. A significant share of these emissions arises from braking abrasion. Coatings can reduce these emissions by over 90%. While laser cladding is already the established coating method in passenger vehicles, its adoption in freight transport is hindered by the complex geometries of commercial vehicle brake discs (e.g. in tractors, trailers, and semi-trailers). In these components, the friction surface is difficult to access through the mounting flange, making it unreachable for conventional optics. The OTI processing optics offer an effective solution, enabling high-performance coatings of brake discs with complex geometries. They are designed for efficient and productive coating, offering cycle times that are in no way inferior to the processes used in car brake disc production.

Which optics are particularly suitable for ID cladding? You can find a selection here.