Actually, what is a diode laser?

The question seems a bit old-fashioned now. Indeed, haven’t we known the answer for ages? At the very least, it’s not like this technology just came onto the market yesterday: it’s firmly established in industry. What did the composer Robert Schumann once say? “There is no end to learning.” In the “century of light”, in which diode lasers also play a key role, it is certainly an appropriate to undertake a deeper examination of the basics and the possible fields of application for this technology. Starting today, we want to do this as part of a mini-series.

The Basics

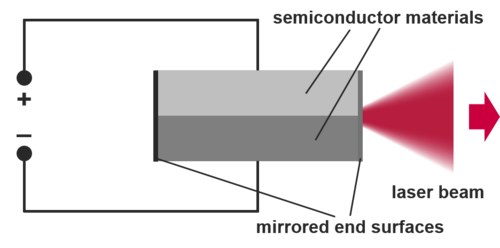

So, what is a diode laser? Maybe we should start by taking a step back and asking: what are lasers in general? The answer begins with Albert Einstein, who first defined the principle of stimulated emission in 1917. This principle states that an excited electron or molecule can deliver energy in the form of light. This stimulated emission is triggered by supplying energy to a light-amplifying material (the laser-active material or medium), ideally,and thus bring it to a higher energy level (an energetically excited state). This energy supply is called “pumping” in terms of laser technology. When the excited electrons or molecules then fall back into their initial state, the previously absorbed energy is delivered in the form of a light beam. Theacronym LASER, in common usage today, stands for exactly this phenomenon: Light Amplification by Stimulated Emission of Radiation.

Which materials are suitable for use as a laser-active medium? This can be a gas or gas mixture, a crystal, or a liquid. The expression “gas or solid-state laser” has to do with exactly these material options and the laser’s specifications that result from them. And as to the diode laser? In these lasers, the laser-active material is a semiconductor, namely, the laser diode. This was developed as far back as 1962, and it creates the laser light via small crystal plates that are supplied with stimulating energy from a power source; hence, it is pumped by electrical energy.

As a result, the diode laser is a semiconductor laser which, therefore, defines its own particular type of laser. However, when things started, there was doubt as to whether it was possible touse this laser, or any other laser, for that matter, in a productive manner. Even the US physicist Theodore Maiman, who constructed the first functioning laser in 1960 (a ruby laser, i.e., a solid-state laser), did not at first expect much from his invention, and merely considered it to be “a solution that is looking for a problem”. The laser diode was not valued any higher. It was not until laser technology was initially used industrially in 1969, namely for welding watch springs, that a rethink took place. Indeed, over the following decades, laser diodes would go on to conquer important fields of application in stage technology and consumer electronics.

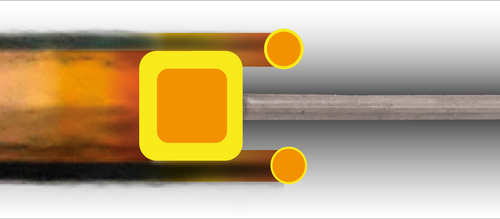

Their use in industrial material processing was, however, only possible due to a change in the laser’s construction, namely, the development of the diode bar. This is a heat sink with lots of laser diodes mounted side by side, meaning that one diode laser can work with hundreds of single laser emitters. This approach was further expanded during its technological development. High-power diode lasers, like those that Laserline produces and sells, are made from stacked diode bars, known as the stacks. There are several of these stacks in a laser, depending on the target output power. In all laser diodes, the emitted light is combined on an optical level in the bars and stacks, withthe laser power being added up to create a high-performance system. At the dawn of industrial diode laser technology, 1 kW was enough of a figure to make people proud. Today, Laserline’s diode lasers are offered as standard in power ranges between 500 W and 25 kW, and with special configurations, even up to 60 kW can be attained in tests. Amazingly, 100 kW can be possible with the current construction method.

However, diode lasers are not only a winning option because of their high output powers: they also popular because of their high energy efficiency. With a socket output efficiency of about 50 percent, they achieve the best efficiency of any laser types available at present. And although a beam of hundreds of single emitters needs to be combined in the diode laser, the technology even reaches very good values with respect to focusing. Laserline’s diode lasers prove themselves with their high brilliance; in other words, they combine their high output powers to generate a high beam quality, i.e., an excellent focus ability. As far as the beam parameter product – a physical parameter that provides information about the focus ability of laser beams – goes, they can attain excellent values of up to 4 mm•mrad.* Special laser concepts that were developed by Laserline have made this possible. Together with high-quality processing optic, which can be used to form the laser beam in a targeted manner, this laser represents a versatile tool: the laser beam does not only strike the workpiece in its traditional round form –it can also do so in a linear, rectangular or square shape.

With their high output powers, brilliance, and excellent energy efficiency, diode lasers are suitable for an array of applications. The emphasis here is on the joining, heat treatment or cladding of metals. However, plastics or print products can also be processed with the help of diode lasers. Need more details? Please take a look at the next part of our series, where we will talk about applications and sectors. But if you can hardly wait, feel free to browse our website right now: our application site is home toa plethora of practical examples.

*For the beam parameter product, the tightest cross section (beam waist; in millimeters/mm) and half-opening angle (beam expansion; in milliradians/mrad) of the laser beam are multiplied by each other. The lower the product, the higher the focus ability, and hence, the better the beam quality.