Modular Direct Diode Lasers for Energy-Efficient Heat Treatment

Laserline’s modular direct diode lasers deliver unmatched energy efficiency, precision, and scalability. With flexible beam shaping, LDL systems set a new benchmark for sustainable, future-ready production.

LDL Lasers Set New Standards in Industrial Manufacturing

High energy prices, stricter environmental regulations, and growing demands for precision and productivity are significantly changing the requirements for industrial heat treatment. In this context, modern direct diode lasers offer an energy-efficient, flexibly integrable solution that is suitable both for the drying of coatings and for complex sintering and tempering processes.

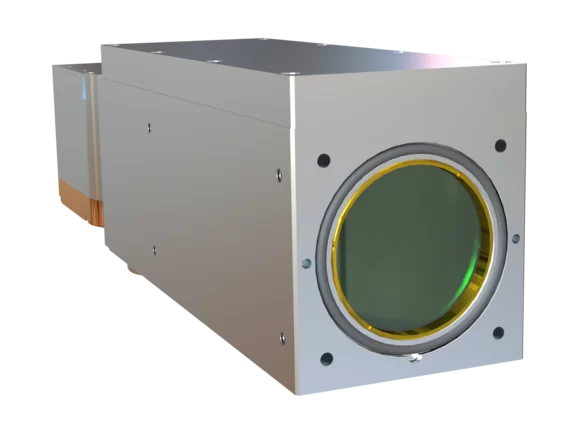

At the core of the direct diode laser technology are semiconductor laser diodes, known as edge emitters, which generate laser light directly. Unlike conventional laser systems with a pump medium and external beam guidance, LDL direct emission lasers require neither additional beam conversion nor optical fibers. The laser power is generated within the compact laser module and delivered directly to the process via projection optics – precisely where it is needed. The elimination of conventional pump media and fiber-based beam guidance not only reduces system complexity and energy losses, but also contributes significantly to the high overall efficiency of direct diode laser technology. At over 56 percent, their wall-plug efficiency is significantly higher than that of other industrial laser systems. This makes them excellent laser sources for thermal applications while also reducing operating costs and improving the CO₂ footprint.

Modular Design for Maximum Flexibility

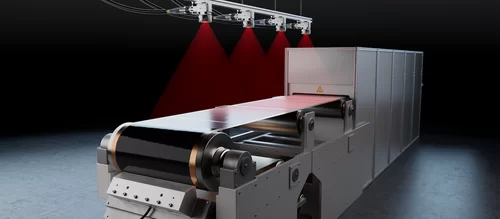

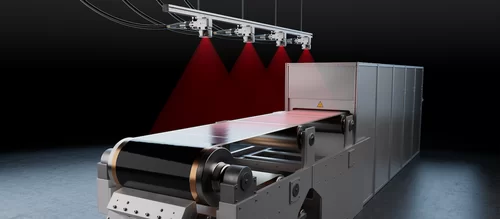

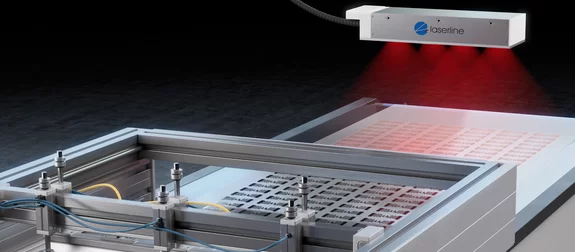

A key feature of Laserline's LDL series is its modular design, which allows adaptation to different process requirements. Each laser system consists of a customizable number of emission zones – typically between one and eight. Multiple modules can be combined to achieve power levels ranging from a few kilowatts to over 30 kilowatts (e.g., 6 × 6 kW), with each emission zone being separately controlled. The laser power can be precisely regulated within milliseconds. This fast response time enables highly accurate energy input control, a clear advantage in process-critical applications. For large-area heat treatment processes such as the conditioning of injection molds or drying of electrode slurry, Laserline offers LDL Multi, a solution with multiple emission zones that ensures uniform and efficient irradiation of large areas. In contrast, the LDL Single model enables parallel irradiation of small UD composite tapes or cylindrical components by using multiple laser heads that can be individually positioned and controlled.

Flexible Beam Shaping and Working Distances

The segmented control also provides the basis for flexible beam shaping: By precisely adjusting individual emission zones, different beam geometries can be created – from homogeneous surface profiles (top hat) to spots with edge intensity peaks or pyramid-shaped beam distribution. In addition, the modular LDL system offers flexible spot configurations – from line spots to rectangular spots. Each model can also be designed as an “endless spot” with spot lengths of several meters for large-scale, uniform energy distribution.

A special feature is the flexibly adjustable working distance: it typically ranges from 300 mm to 1,500 mm and enables laser spots with lengths in the meter range even at the smallest working distances. This makes it possible to process both fine and large-scale structures efficiently and homogeneously without moving components or additional beam-shaping units. The combination of segmented power control, variable beam geometry, and flexible working distance opens up a wide range of possibilities for customizing thermal processes to specific materials and applications, for example through local power adjustment or profile-accurate spot trimming.

Compact Design for Easy Integration

Thanks to their compact and integrated design, LDL systems are particularly easy to integrate into existing production environments – keyword: retrofit. They are modularly scalable and require no sensitive or maintenance-intensive components such as external fibers or complex optical deflection units. This reduces overall complexity of the system and lowers both investment and maintenance costs in the long term. Hybrid systems can also be implemented, for example by combining them with existing convection drying systems.

Wide Range of Applications

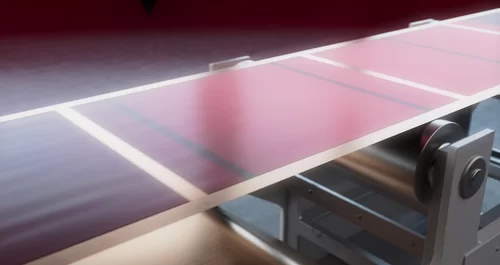

LDL laser systems open up an ever-growing range of industrial applications. Thanks to their direct photon emission and high wall-plug efficiency, they are ideal for energy-efficient heat treatments such as drying and curing of functional coatings, for example in the production of battery electrodes, paints, or polymer coatings. In these applications, direct diode lasers enable homogeneous heating of large surfaces with high reproducibility, while significantly reducing process times and energy consumption compared to conventional convection or infrared methods. The possibility of a large working distance makes LDL laser systems particularly suitable for challenging applications in the chemical, metal processing, and process industries.

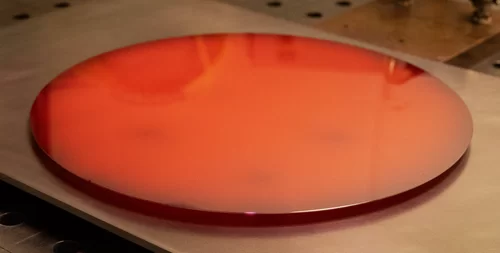

Direct diode lasers are also opening up new possibilities in semiconductor manufacturing. Annealing, the selective tempering of thin material layers or wafers, places high demands on thermal precision. Thanks to segmented power control, LDL systems enable precise temperature control without affecting surrounding structures. In sintering, the systems enable the contactless fusion of materials such as powders or pastes, for example in metallic or ceramic functional coatings, creating dense, homogeneous layer structures with minimal thermal stress. They also support integrated temperature monitoring, which facilitates precise process control and quality assurance.

Energy Savings and Process Optimization

In addition to their technical advantages, LDL systems also offer significant economic and ecological savings potential. In typical applications, energy consumption and CO₂ emissions can be reduced by more than 50 percent compared to conventional heating systems. In battery production, for example, the use of LDL lasers can cut operating costs by up to 28 percent and reduce the required plant footprint by nearly half – a decisive advantage given the growing space constraints in manufacturing.

Future-Proof Technology for Industrial Applications

The LDL series offers manufacturers a system designed for maximum efficiency, high scalability, and easy integration. The systems can be individually customized and adapted to a wide range of process requirements. This makes them a future-proof solution for modern manufacturing processes in a wide variety of industries.