The blue diode laser revolutionizes the processing of copper, gold, and other highly reflective metals in multiple respects.

World-leading High Power Lasers

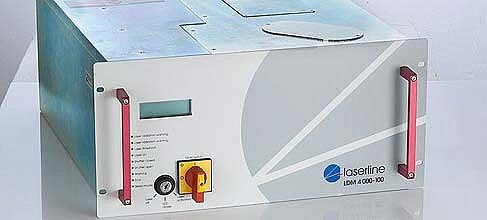

Laserline’s high power lasers can achieve a standard laser power of up to 25 kW and an efficiency rate of almost 50%. Meanwhile, in the power class of up to 4 kW, it is now possible to purchase converter lasers with a beam quality of up to 4 mm. Additionally, the long-lasting industry lasers are low maintenance, thanks to an innovative diode cooling technology that has been compactly and portably built, and they are even available as a 19" rack mount laser. Furthermore, customized laser designs have been designed, created, and thoroughly tested in our own application laboratory. Additional components, such as processing optics, scanners, beam switches, and monitoring systems, round off Laserline’s growing portfolio. Our operators can participate in training sessions and make use of service/maintenance contracts. In case of malfunctions, a 24/7 service hotline and teleservice with remote diagnosis and remote maintenance are available for the best possible end-to-end service.

Diode Lasers – Getting Light from Electricity directly

Laserline’s high-powered lasers are characterized by the direct use of diodes as the most efficient form of beam generation. The basic advantage of high-power diode lasers lies in the direct transformation of electricity into light without the indirect route of passing via a pump medium. This means that diode lasers are more compact, more efficient, more mobile and easier to handle than all the other lasers. Diode lasers are a winning option: they are almost maintenance-free and have long lifetimes.

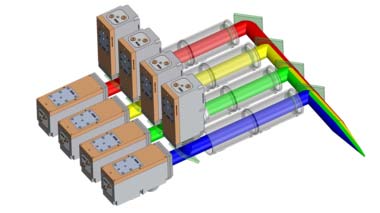

The diode – the heart of beam generation

The laser beam source includes several diode laser stacks, consisting of single diode bars. The number of bars per stack and the total number of stacks determine the output laser power and the required beam quality. With the help of simple, patented technology, the beams of the individual diodes are overlaid into one common laser beam and coupled into a fiber-optic cable. In most cases, the modular design of the laser head makes it possible to further equip the systems with more stacks so as to increase its power subsequently.

High-power lasers that are verging on zero-maintenance

Reliability and process efficiency are key requirements for tools used in industrial production. Fail-safe continuous operation in a multiple-shift operation, including in difficult ambient conditions, is, therefore, the benchmark for our products in terms of quality.

The highest possible process stability and system availability in a triple-shift operation are the requirements in the automobile industry, as fulfilled and proven by the diode lasersin a host of applications for years now. With an almost zero-maintenance operation and a lifetime of much more than 30,000 operating hours at its highest efficiency, the direct diode laser is clearly superior to other laser beam sources. As a comparison: with lamp-pumped Nd:YAG lasers, the lamps need to be changed about every 1,000 operation hours, which always entails downtime and service costs.

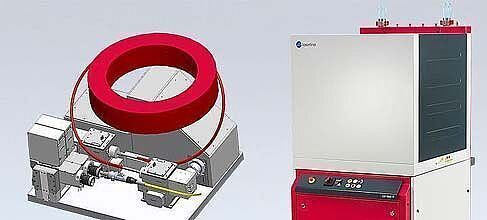

Fiber-coupled diode laser requiring minimum space

Space requirements in production have become an important criterion for planning production lines. As a result, an added plus for LDF diode lasers compared to other lasers of the same performance class is the small amount of space they require – less than 1m² floor space. The compactness and robustness of the diode laser and high-power laser optics even allow for mobile use, if and when necessary, enabling wholly new service and backup strategies.It can be replaced fairly easily and quickly in the event of maintenance work or in the case of malfunctions. This means that maintenance or repair can take place separately from the production line, and, by extension, without production downtimes. It takes less than half an hour to exchange and the laser does not need to undergo new setup or programming. Service calls from customers or Laserline technicians regarding high power diode lasers are, as a result, significantly more flexible.

Powerful – compact – individual

This philosophy has given rise to lasers that, today, offer up to 25 kW power as standard and can even reach an unusually high efficiency of almost 50 percent. Meanwhile, converter lasers with high beam powers of up to 4 mm mrad are available in the power class of up to 4 kW. Laserline’s diode lasers are long-lasting, low-maintenance, and compactly built for mobile use thanks to their innovative diode cooling technology, and they are even available as a 19" rack mount laser. Furthermore, customized laser designs are designed, created and thoroughly tested in our own application laboratory. Additional components such as processing optics, scanners, beam switches, and monitoring systems round off Laserline’s growing portfolio. Users are offered training, as well as service and maintenance agreements. In case of malfunctions, a 24/7 service hotline and teleservice with remote diagnosis and remote maintenance are available.

Wide field of application

Typical fields of use for Laserline’s diode lasers includetraditional industrial applications in material processing, such as welding, brazing, hardening, softening, and creating or repairing coatings. Additionally, Laserline’s diode lasers have become established within plastic welding and in newer manufacturing processes, such as additive manufacturing (metal 3D printing) or the welding of fiber composites. Users primarily come from the automotive industry, or the engineering, toolmaking and mold-making industries. Many companies in the aerospace industry and heavy industrycount on Laserline today, too.

Interested in our diode laser systems for applications in industrial materials processing?

Contact us!