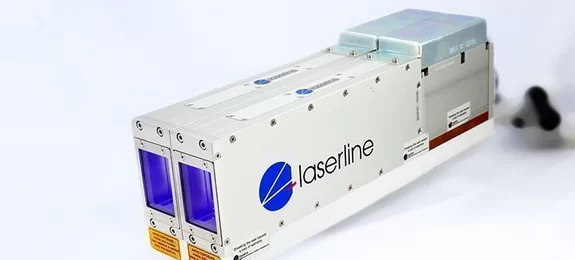

LDL Series |

Direct Diode Laser

Compact direct diode laser for efficient large area heating, laser metal deposition applications and more

Compact direct diode laser for efficient large area heating, laser metal deposition applications and more

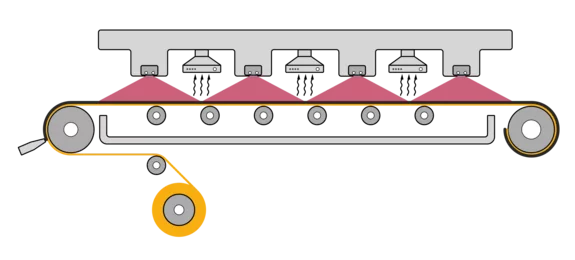

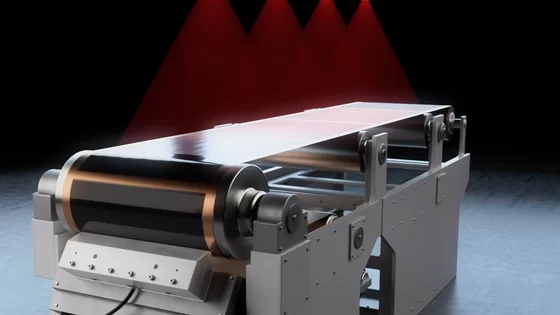

The new LDL direct diode laser systems provide a compact and efficient solution for modern heat treatment. By eliminating optical fibers, the design reduces costs and complexity, improving both reliability and usability. With direct photon emission from diode edge emitters, the system achieves a wall plug efficiency of over 56%, setting new standards in energy performance. By cascading the LDL modules, the innovative module concept facilitates large-area irradiation across several meters in length. At the same time, the system size is significantly reduced. The ability to work with minimal or remote working distances creates maximum design flexibility adapting the system to specific application requirements.

Energy efficiency

Modular

Tailor made

Cost effective

Compact

Beam shape control

Flexible and simple to implement

Efficient and reliable

Guaranteed future proof

| LDL 13,000 | LDL 34,000 | ||||

|---|---|---|---|---|---|

| Max. Laser Power | 13,000 W | 34,000 W | |||

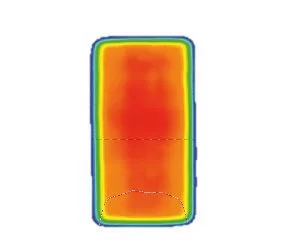

| Spot Sizes* | 300 x 400 mm² | 600 x 600 mm² | |||

| Working Distance* | 300-1500 mm, tailored to customer specifications, various configurations available | ||||

| Wavelength Range* | 980 nm | ||||

| Number of Laser Emission Zones* | 3-8 | ||||

| Power Range | 10% to 100% of nominal power | ||||

| Rise Time | < 10 ms (10/90) | ||||

| Homogeneity | +/- 2% | ||||

| Wall Plug Efficiency | > 56% | ||||

| Weight | Approx. 13 kg | Approx. 22 kg | |||

| Dimensions | Approx. 165 x 97 mm² (WxH) x customized head length | ||||

*Various configurations available, depending on customer specifications

A standard LDL direct diode laser may not provide the necessary performance characteristics for your specific application. To ensure optimal results, we offer a customized direct diode laser solution, engineered and developed according to your exact requirements, including wavelength, power output, beam quality, and integration parameters.

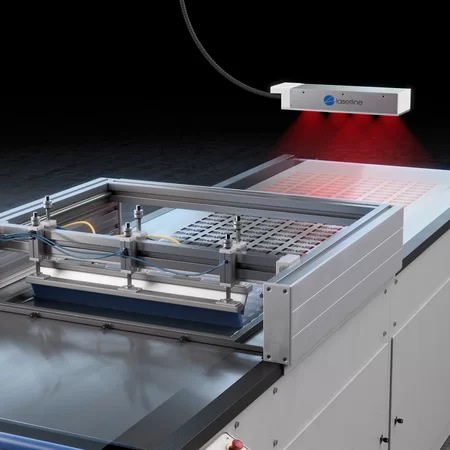

An ultra-compact direct diode laser for heat treatment applications, with a housing width of only 50 mm. The processing head with integrated beam source and optic generates rectangular, fully homogenized laser spots that can be adapted to the process requirements. Multiple processing heads can be cascaded to form a system setup.

Highly robust and protected direct diode laser for harsh process environments.

Diode lasers have been used in the manufacture of CFRP components since 2009. For the tape laying and tape winding of fiber-reinforced plastics, the tapes that have been laid down or wound are welded using lasers. The improved mechanical properties of the products and weight savings of up to 70 percent are leading to a continuous increase in the applications involving CFRP (carbon fiber-reinforced plastic) components. However, current production systems using a single machining head have a limited maximum yield. In order to increase the production capacity of tape application systems, Laserline developed a modular direct diode laser with a housing width of less than 50 mm. The design allows several heads to be integrated into one clamping. The processing head, with an integrated laser source and optic, generates a rectangular, fully homogenized laser beam that can be adapted to the tape sizes in question. The maximum laser power of more than 2 kW per processing head ensures high process speeds and guarantees that the tape material will melt reliably. A high working distance of more than 200 mm enables production to be both contamination-free and collision-free. The use of nothing but industry-proven standard components makes certain that processes can be started up swiftly and reliably.

An important field of application for diode lasers in the industrial sector is laser cladding or laser metal deposition (LMD) for the production of high-quality laser coatings. Components enhanced by diode laser cladding are used, for example, in mining, agricultural machinery or vehicle production. Special application or integration requirements make the use of fiber-coupled diode lasers difficult in individual cases.

The design concept of this direct diode laser, which was developed for integration into a complex cladding system for engine components, is particularly suitable for harsh process environments. The process head meets the requirements of protection class IP64 and is also designed for moving operation with high accelerations.

The modular beam sources of the LDL direct diode lasers enable fast and economical realization of customer-specific solutions for special applications and installation situations.

Interested in our direct diode laser solutions?

Get in touch with us!