熱伝導溶接

”穏やかな”レーザ材料加工 – 優れたシーム品質 – 再加工、 後処理加工不要– 高い経済性

”穏やかな”レーザ材料加工 – 優れたシーム品質 – 再加工、 後処理加工不要– 高い経済性

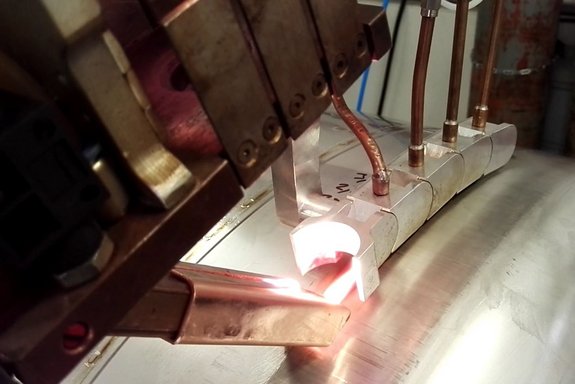

ダイオード伝導溶接は、最大1ミリメートルという低い照射深さが特徴で、主に材料厚の薄いシートの接合に使用される。熱伝導溶接では、レーザーが意図した接合部に沿ってシートを溶かす。接合部の溶融部分が合体し、その後冷却されて実際の溶接シームが形成される。これにより、通常の溶接方法よりも材料の歪みが少なく、より迅速に溶接接続を実現することができる。さらに、後処理を必要としない、滑らかで気孔のない溶接継ぎ目ができる。このため、熱伝導溶接は、特に目に見える部分で選択される方法となっている。

Laserline社のダイオードレーザは、均一な出力と均一な強度分布(トップハットビームプロファイル)により、優れたシーム品質と高い加工安定性を保証し、いくつかの点で熱伝導溶接を最適化します。さらに、30,000時間以上の稼働時間、高効率、低メンテナンス性など、Laserline社のダイオードレーザは、他のビーム光源よりも明らかに優れています。

どこの家庭にも、どこの工場の食堂にもあるステンレス製シンク。しかし、溶接の継ぎ目はある。その継ぎ目が見えないのは、Laserline社のダイオードレーザが関係しています。熱伝導溶接を可能にし、溶接跡を残さず、技術的にも経済的にも最適なソリューションを提供します。

金属ベローズは、パイプラインの熱膨張を補正する必要がある場合や、真空ポンプと測定器の間の振動を減衰させる必要がある場合に使用されます。薄くてフレキシブルなメンブレンペアの溶接には、クラックのない安定した溶接シームを形成する均一な入熱が必要です。Laserlineのダイオードレーザは、熱伝導溶接で優れた結果を提供します。

熱伝導溶接に特に適したレーザーシステムは?ここではその一部をご紹介します。