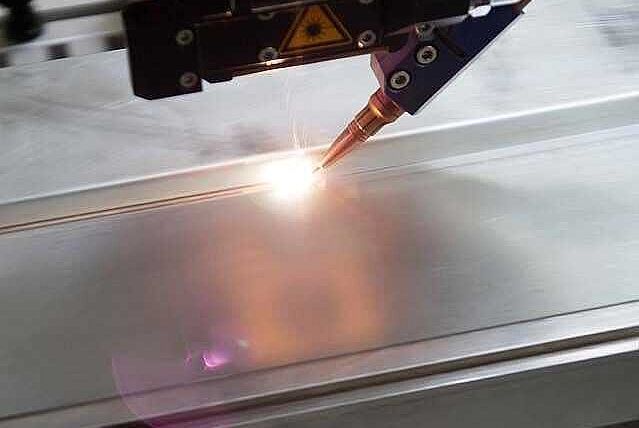

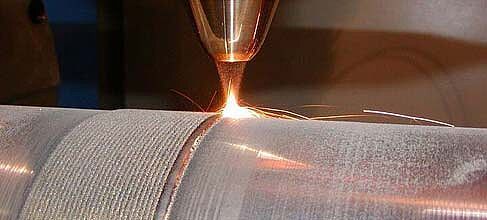

Hardly any sector of industry can do without laser welding: almost every production process includes metals and plastics that need to be joined together. Laser beam welding is ideal for this, especially when high welding speeds, narrow welding seams and low thermal distortion are required.

Are you interested in our diode laser systems

in applications for industrial laser material processing?