Page 1 - Laserline-Case-Study-Coating-solutions-for-boiler-tube-systems

P. 1

Coating Solutions for Boiler Tube Systems

Task Result

Boiler tubes in biomass and waste incineration plants are The result was a coating process that is a combination of

exposed to extreme operating conditions. To create vapor thermal spraying and cladding, and which combines the

pressure within the pipes that makes an effective drive of advantages of both technologies. Whereas during plasma

the power plant turbines possible, flue gas temperatures spraying, a noble gas (ionized by an arc) serves as energy

of up to 1000 °C must be realized within the combustion source, at laser spraying this role is taken over by the

chamber of the boiler. No pipe-material will sustain the beam of a diode laser. When impinging the component’s

chemical processes induced in this way for very long. surface, it creates a calm molten pool with very low-

Already at temperatures of 350 °C, the chlorine in the flue impact depth. The powder particles of the coating material

gas increasingly reacts with the iron of the ferritic pipe are blown into this molten pool via argon stream where

materials. In order to improve the lifetime of pipes, many they are melted. After solidification of the coating material,

power plant operators count on metallic or ceramic a homogeneous, almost pore-free protective layer is

corrosion protection coatings. With their help, the material formed.

decomposition process can be delayed and the lifetime of

the pipes can be significantly extended.

Process

Häuser & Co. in Duisburg, Germany, is a manufacturer

that is specialized in coating solutions for boiler tube

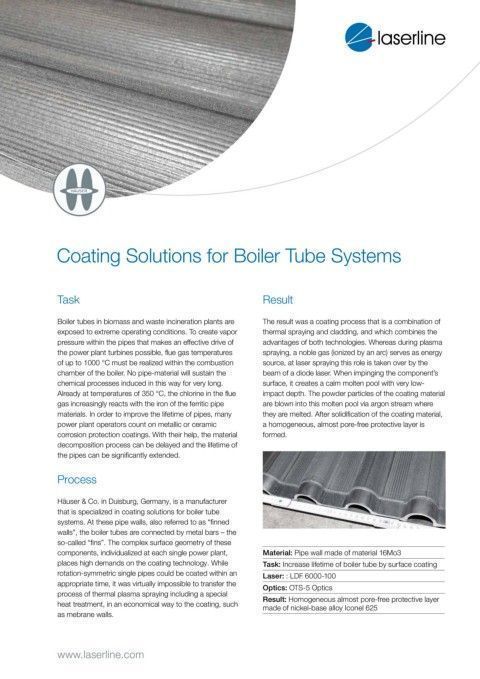

systems. At these pipe walls, also referred to as “finned

walls”, the boiler tubes are connected by metal bars – the

so-called “fins”. The complex surface geometry of these

components, individualized at each single power plant, Material: Pipe wall made of material 16Mo3

places high demands on the coating technology. While Task: Increase lifetime of boiler tube by surface coating

rotation-symmetric single pipes could be coated within an Laser: : LDF 6000-100

appropriate time, it was virtually impossible to transfer the Optics: OTS-5 Optics

process of thermal plasma spraying including a special

heat treatment, in an economical way to the coating, such Result: Homogeneous almost pore-free protective layer

made of nickel-base alloy Iconel 625

as mebrane walls.

www.laserline.com