Additive manufacturing applications – overview

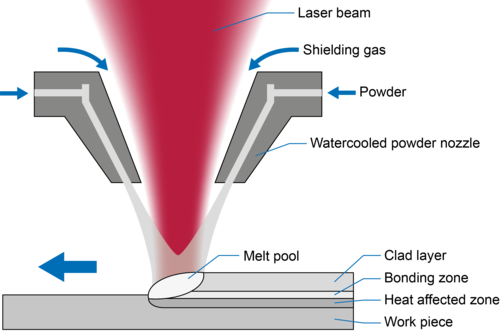

How does additive manufacturing work? The main tool involved in metal additive manufacturing is a system which contains a laser, a movable metal deposition head and a metal powder nozzle or wire feeder. The metal deposition head, which is suitable for 3D printing, is moved over a building platform while it adds the metal powder or the wire by heating it with the laser beam and melting it on the surface. After the material has been cooled down, the next metal layer can be applied, thereby additively generating a three-dimensional component in accordance with the construction plan. The technical principle of the additive manufacturing process is basically the same as the cladding process. The difference is that it does not revolve around two-dimensional layers: instead, three-dimensional forms are created.

The process advantages of the diode laser

The top-hat beam profile of Laserline’s diode lasers creates very even molten pools and allows calm process control that leads to homogeneous, crack-free layers of material. One of the most promising approaches for optimized production processes is the integration of laser beam sources into machine tools for additive manufacturing products.